Fresh Corn Thresher | Sweet Corn Threshing Machine | Sweet Maize Sheller

Fresh Corn Thresher | Sweet Corn Threshing Machine | Sweet Maize Sheller

Sweet corn shelling machine | Fresh sweet maize threshing machine

Features at a Glance

The fresh corn thresher can thresh all kinds of fresh corn, sweet corn, waxy corn, cooked corn, and corn after thawing. It can handle up to 600 kg of fresh corn kernels per hour, boosting efficiency by more than 30 times compared with traditional manual threshing, completely solving the problem of labor shortage and low efficiency during busy farming seasons.

The unique anti-damage design of the sweet corn sheller ensures that every grain of corn is full and undamaged, and the threshing rate is as high as 98%. It is suitable for factories and enterprises such as central kitchens, canned corn kernels, quick-frozen corn syrup, corn kernel factories, dry food processing, agricultural and sideline products processing, etc.

Multiple sweet corn sheller machines can work with large-scale assembly lines, for example, corn threshing and washing production lines. A single machine can be used for food processing, such as canned corn production and processing workshops, etc.

Fresh corn threshing machine structure and features

The whole fresh corn thresher machine is made of stainless steel, which can fully adapt to the humid environment of the processing center. Its main components are shown in the figure below.

- Reasonable design: the whole machine is made of stainless steel, and it is easy to move with casters. The frequency converter controls the speed and the operation is simple.

- Convenient feeding: the feeding port is equipped with a chain feeding device, which effectively improves work efficiency.

- Discharge port: it is equipped with a blower to make the corn kernels clean and beautiful after being removed.

- Strong adaptability: it is not only suitable for large-scale production in factories and assembly lines but also suitable for processing in family workshops.

- High threshing rate: it is suitable for the threshing of various sizes of corn, and the depth of threshing is adjustable.

- Knife tools with a long service life: they are made of special stainless steel material, undergo special process treatment, require no long-term sharpening, and are durable.

Working principle of threshing sweet corn

Place peeled fresh corn on the conveyor chain

- The corn is fed into the corn machine one by one by the conveyor chain.

- The conveying system uses a stainless steel chain for uniform-speed transportation. V=15 m/min.

- Feeding the corn.

- The rubber roller rotates in the direction of the arrow, clamping and transporting the corn cob into the cutter.

- The rubber roller is made of a special non-toxic material with a soft and elastic texture. It ensures that the ultra-thin-skin corn will not break or burst.

Core structure-separation of kernel and stem

- Unique knives and cutter heads can easily cut corn ears of different diameters.

- A five-piece knife rotates at a high speed, close to the corncob.

- The cutter rotates counterclockwise to cut the ears of corn.

- The cutting tool is made of high hardness, high toughness, and high wear-resistant materials. Currently, it has gone through several stages of development, which greatly extends the sharpening cycle and significantly improves production efficiency.

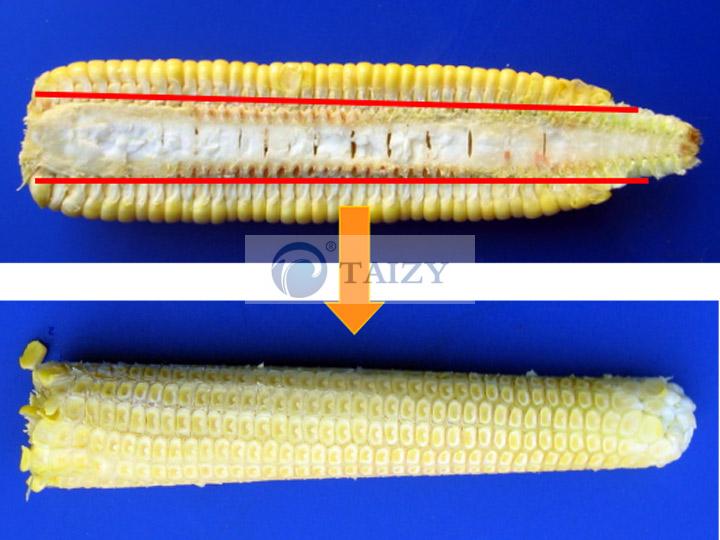

Radial cutting of corncob

- The cut is neat, smooth, and dry, without damaging the contents of the kernel.

- The cutting depth is adjustable, and it can meet the needs of users at all levels.

Axial cutting of corncob

- Axial tapered cutting can be achieved, which greatly improves the yield of corn kernels.

- Smoothly cut special-shaped corn and curved corn.

- The minimum length of the corn ear for cutting is 80mm.

Corn cob discharge

- There is a toothed disc cutter in the middle of the plastic roller.

- The corncob can be clamped, transported, and discharged.

- The corncob is led out coaxially by two sets of four discharging wheels, which enhances the stability of discharging and avoids jamming.

Electrical control

The entire operation process of the fresh corn thresher is controlled by a motor. The machine is equipped with operation buttons, and there is an inverter in the internal structure.

Application of fresh corn thresher in production lines

In the corn canned food processing plant, you can use multiple fresh corn thresher machines if you want a big capacity at the same time. You can wash, pack, freeze, and sell after threshed.

Advantages of sweet corn shelling machine

Nowadays, canned goods, various corn side dishes, and people use corn in their daily lives. Therefore people have a high demand for fresh corn. And the production of fresh corn in large quantities has become a common phenomenon. The machine material is safe food-grade stainless steel, producing clean and hygienic corn kernels.

- Increased efficiency: sweet corn shellers can process large quantities of corn in a short period, which can help reduce labor costs and increase productivity for large corn processing plants.

- Consistency: fresh corn threshers can peel corn consistently and with virtually no breakage, helping improve the overall quality of the corn and reduce waste.

- Improved food safety: sweet corn threshers are designed to peel corn kernels without contamination, which is especially important for companies that sell sweet corn as a food product.

- Adaptable: the threshing section of our sweet corn shellers automatically adjusts to the specific size of the corn, allowing them to handle corn of all diameter sizes.

Generally, large fresh corn processing plants will use more than one fresh corn threshing machine to start work at the same time.

Sweet corn sheller technical information

| Model | HYMZ-268 | HYMZ-368 |

| Voltage | 220V 1 phase | 220V 1 phase |

| Motor | 1HP+1/2HP+1/4HP | 1HP+1/2HP+1/4HP |

| Production | 400-500kg/h(seeds only) | 600kg/h(seeds only) |

| Input conveyor size | Without | 690*260*380mm |

| Machine size | 630*620*1250mm | 1320*620*1250mm |

| Machine weight | 100kg | 100kg |

Fresh corn shelling machine sold to America

A customer from the United States purchased a fresh corn thresher for his use. During the communication with the customer, we will provide any information about the machine. For example, pictures, videos, parameters, structure, etc. of the fresh corn thresher.

We will also be ready to answer any questions the customer may have about the machine. In addition to the fresh corn thresher, the customer also purchased a set of blades.

After the customer has purchased the fresh corn thresher, we will provide the manual and instruction manual. Therefore, customers do not have to worry at all about not knowing how to operate the machine.

FAQ about sweet corn threshing machine

Can this machine peel corn?

No, when threshing with a sweet corn thresher, you must remove the husk before putting it into the machine. We have other types of corn peeling and thresher.

Is the speed of the knife adjustable?

The rotation speed of the knife is controlled by the frequency converter, and the feeding speed is fixed.

Can corn be withdrawn?

Yes, it can. The fresh corn thresher is equipped with a feeding wheel reversing and rewinding device. If the corn cob is broken or stuck, press the reversing button to make it exit smoothly.

What is the output of a fresh sweet corn thresher?

The machine can thresh 75 corn per minute, and the yield is about 300 kg/h (corn kernels).

Contact us at any time

Farmers and agricultural entrepreneurs are welcome to actively inquire about our fresh corn thresher! We are committed to providing you with efficient and reliable solutions and provide a full range of pre-sales consultation and after-sales service support. Look forward to working with you!