Straw Forage Silage Harvester Machine With Tractor

Straw Forage Silage Harvester Machine With Tractor

Stalk crushing and recycling machine | Forage chopper and harvester

Features at a Glance

This silage harvester and recycling machine is mainly used to cut silage and then crush it into small pieces by rotating blades. These small pieces are lifted to upload to the container. This chaff harvester must match a 60Hp tractor and its capacity can reach 0.25-0.48 ㎡/h. The recovery rate is more than 80%.

The harvesting width is 1.3 m and we also have other types with 1.35 m, 1.5 m, 1.65 m, 1.7 m, 1.8 m, and 2 m cutting width. You can choose one according to your needs. Also, we can customize this type of straw harvester machine for you.

Technical parameters of silage harvester machine

| Name | Chaff harvester |

| Engine | ≥60HP tractor |

| Dimension | 1.6*1.2*2.8m |

| Weight | 800kg |

| Harvesting width | 1.3m |

| Model | GH-400 |

| Recycling rate | ≥80% |

| Fling distance | 3-5m |

| Fling height | ≥2m |

| The length of crushed straw | Less than 80mm |

| Rotating blade | 32 |

| Cutter shaft speed(r/min) | 2160 |

| Working speed | 2-4km/h |

| Capacity | 0.25-0.48h㎡/h |

As for the silage harvester, the recycling basket is related to the horsepower of the tractor and the cutting width, and you can consider the following for reference.

| Cutting width | With Recycling basket or not | Horsepower of tractor |

| 1m | Yes | ≥60hp |

| 1.3m | Yes | ≥70hp |

| No | ≥40hp | |

| 1.5m | Yes | ≥75hp |

| No | ≥50hp | |

| 1.65m | Yes | ≥90hp |

| No | ≥55hp | |

| 1.8m | Yes | ≥100hp |

| No | ≥60hp | |

| 2m | Yes | ≥110hp |

| No | ≥70hp | |

| 2.2m | No | ≥75hp |

| 2.4m | No | ≥90hp |

With different cutting widths, the parameters are different as well, and the specification of a 2.4m cutting width is as follows. 58 sets of blades are installed on the silage harvester machine, and it should match with more than a 90HP tractor.

| Model | TZ-2400 |

| Recycling Box | Without |

| Working Efficiency | 1.3-1.7 acre/H |

| Blades | 58 pcs |

| Cutting Height | 30-220mm |

| Cutting Width | 2.4M |

| Power | ≥90HP Tractor |

| Dimension | 3.2*1.75*1.55M |

| Packing Dimension | 3.45*2*1.8M |

| Gross Weight | 1000kg |

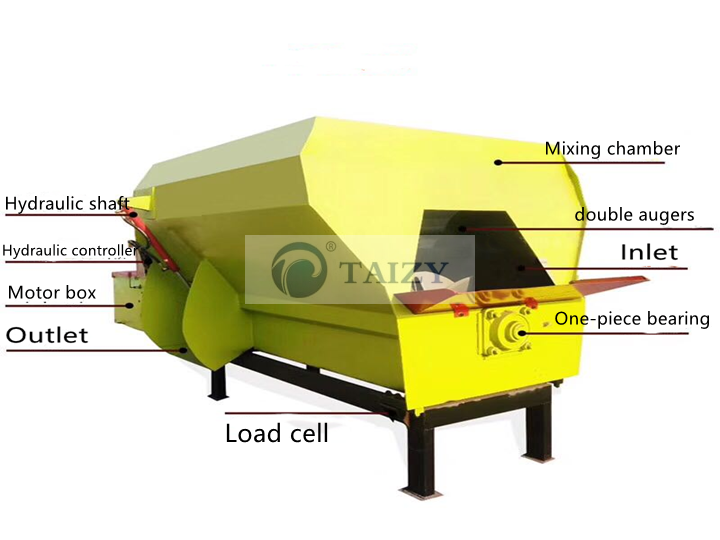

Structure of straw harvester recycling machine

Straw recycling machines are mainly composed of the following parts.

- crushing chamber

- hydraulic automatic unloading device

- 60HP tractor

- crushed straw container

- PTO driven

- hydraulic device

Application of corn straw silage harvester

Grain stalks such as corn, sorghum straw, cotton straw, banana stalk, and other grasses all can be the raw materials. The final product of the chaff harvester can be used to feed animals and add the nutrition of soil etc.

Straw silage harvester machine working principle

- Firstly operator connects the grass cutter machine with a tractor.

- 32 rotating blades constantly cut the straw when it begins to work.

- The straw goes into the crushing part.

- Then the fan blows the small pieces into the lifter.

- The lifter conveys the small pieces into the container.

- Finally, the hydraulic device on the tractor powers the machine to unload the crushed straw.

How to install a straw crusher recycling machine?

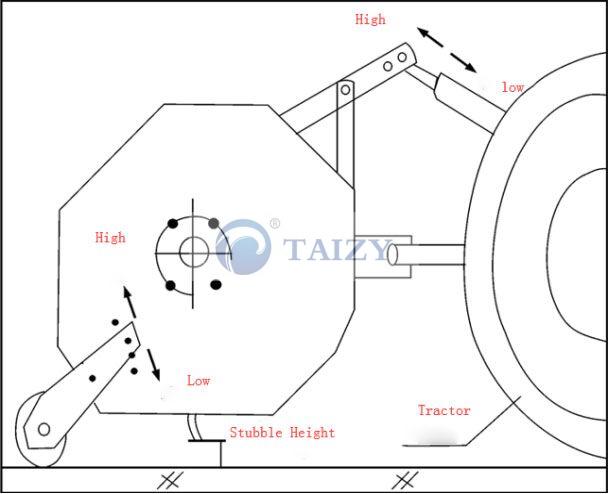

- The operator should first connect the straw harvester to a tractor and then adjust the horizontal and vertical levels of the tractor and the stubble height. The length of the tractor’s suspension rod on both sides should be horizontal.

- Adjustment of the height of the chopper knife from the ground. Adjust the position of the ground wheel to the hole on the side plate. Adjust the length of the pull rod according to the humidity of the soil, as shown in the picture below.

Straw chopper machine advantages

- The crushed silage can return to the field again, which can add to the nutrition of the soil.

- Silage harvesting machines can work at high speed and can effectively improve working efficiency.

- Due to the hydraulic device, crushed silage can be unloaded easily.

- The recycling rate is more than 80%.

- 32 blades can fully cut the straw.

Straw crushing harvester machine preoccupation

- Check and tighten the fasteners of joints.

- Remember to remove the clay to avoid whelming the working load of the machine.

- Lacking oil towards the bearing gap may trigger excessive temperature, and the operator should add it in time.

- Open the fan cover and check whether the screws on the blade hub are loose. If loose, tighten them in time.

- Before using the silage harvester, first check whether the components are intact and whether the fasteners are loose or not, and add gear oil to the gearbox.

- The oil height is higher than the gear teeth. Add lithium molybdenum disulfide grease to each lubrication part.

- After the inspection is completed, the corn stalk silage harvester should idle for 5-10 minutes to confirm that the components are in good working condition.

- There is no abnormal noise before use.

Operation introduction of silage harvester

- When working, the silage harvester should be adjusted to a height of 20-50 cm from the ground (the lifting position should not be too high so as not to cause damage due to the excessive angle of the universal joint). At the same time, you shall gradually adjust the hydraulic lifting handle to a specific height that is as same as the required grass height.

- During operation, the number of rows and the speed of the corn silage harvester should be determined according to the density of the straw planting and the horsepower of the tractor respectively to ensure normal operation.

- it is forbidden to hit the soil. If that happens, you should adjust the height of the upper rod.

- you should always pay attention to observe whether the straw running outlet is smooth. If there is no straw thrown at the outlet, you should stop immediately and check if the fan is blocked.

- When turning, the straw harvester should be lifted, and lowered after turning. Straw harvester should keep stable when lifting and landing, and it is forbidden to reverse during work.

- During the operation, you should remove the grass and other obstacles. The ground should be reserved for the 3-5 meter space for the machine.

- Stop the operation immediately if you hear abnormal noise during the operation, and continue the operation if everything is normal.

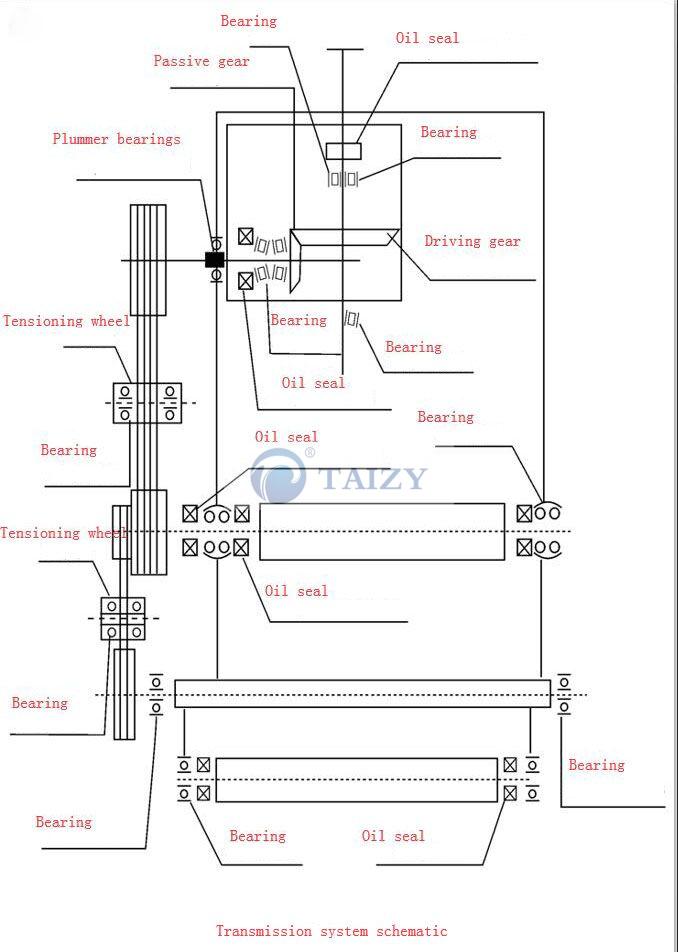

- Check the tightness of the belt at any time during the operation in the case of reducing the speed of the cutter shaft and affecting the quality of the crushing effect and the wear of the belt.

Maintenance of the straw harvester

It is important to check the machine regularly and maintain it in time if there is something wrong.

maintenance

- Check and tighten the fasteners at the joints.

- Check the gearbox sealing condition. The static joint surface does not seep oil, and the moving joint surface does not drip oil. It is necessary to replace the seal and oil seal.

- Adding molybdenum disulfide lithium base grease to each lubrication point.

- Remove the clay promptly to avoid increasing the working load of the machine.

- Check the temperature rise of each bearing. If the temperature rise is too high, it is caused by the excessive bearing gap or lacking oil. It should be adjusted or refueled in time.

- Open the fan cover and check whether the screws on the blade hub are loose. If loose, tighten them in time.

Quarterly maintenance

- Clean the gearbox and replace the gear oil.

- Thoroughly remove the dirt, weeds, and oil on the straw harvester.

- Remove the V-belt and store it separately.

Successful cases of silage harvester machine

This year, our customers from Pakistan and Ecuador ordered 10 sets of straw cutter machines with great satisfaction. He asked us to know many details about it such as capacity, cutting width, tractor, recycling rate, etc.

We aim to solve every problem our customer has provide the best service and always keep our original aspiration as a salesman. Influenced by patience and professional skills, he introduced our hay straw harvester machine to his friends after receiving the machine.

| Malfunction | reason | solution |

| The universal joint shaft is broken | 1. The transmission system has been jammed 2. Sudden overload during operation | Replace universal joints

|

|

The machine vibrates strongly | 1. The flail knife is broken and falls off. 2. The fastening bolts are loose3. The rotating part has a collision4. Bearing has been damaged5. Universal joint has been installed mistakenly | 1. Replace 2. Tightening 3. Check4. Replace5. Install in the correct way

|

| The V-belt is severely worn | 1. The tension is not enough

2. The belt length is inconsistent | 1. Adjust 2. Replace |

|

The gearbox has noise and the temperature it rises | 1. The gear gap is not suitable. 2. Gear oil is damaged3. Too much or too little lubricant oil | 1. Adjust the gap 2. Replace the gear 3. Reduce or replace lubricant oil |

| Increased bearing temperature | 1. Lack of oil 2. The driving shaft is distorted3. The triangle belt is too tight4. The bearing gap is too close | 1. Add enough lubricated oil 2. Re-adjust to flexible rotation 3. Appropriate adjustment4. Adjust the gap |

| Bad harvesting effect | 1. V-belt slips 2. The flail knife is seriously worn3. The working speed is too fast | 1. Appropriate adjustment 2. Replacement3. Reduce walking speed |

| straws are not discharged from the outlet, and the machine is clogged. | 1. Blockage in the fan 2. The fan shaft is in normal operation3. The blade and the fan shaft have a reverse rotation4. V- belt slips5. The amount of straw fed is too much | 1. Open the inlet to clean up the blockage. 2. The machine moves forward when the fan is running normally,3. Fix the blade4. Tension the V-belt5. Reduce the speed of the machine6. Reduce the working rows |

FAQ

How to collect hydraulic devices with a tractor?

There are two ways to link hydraulic devices according to the collecting ways of the tractor as in the above picture. The left one is a vertical link and the right one is a horizontal link.

How many rotating blades are inside the machine?

32.

How many types of silage harvesters do you have?

We have 6 types and each one has different capacities, please get in touch with us to know more.

What is the height of silage harvesting from the ground?

20-50cm.

What should be done if the machine hits the soil?

Adjust the upper rod on time.

Why there is no straw thrown from the outlet?

The fan at the side of the silage harvester may be blocked.

Can the straw storage part be unloaded?

Yes, the crushed straw will directly drop into the field, which can be considered as fertilizer to greatly increase the nutrition of the soil.

If you want to buy a pasture harvester, why choose us?

To be honest, we have a strong product line and professional technical workers for the stalk harvester machine. We invest great time and energy to produce every spare part even a small screw. We never let you down if once you choose us. Welcome to contact us and visit our factory at any time!

Contact us at any time

For more detailed information about the straw crushing and recycling machine, or if you would like to experience the performance of the machine for yourself, please feel free to contact us. We warmly welcome you to visit our facility to see how our technical team and product specialists will meet your unique needs.