Uganda’s agriculture sector is spearheading a national livestock initiative to procure 250 silage chopping machines. This effort is designed to enhance the efficiency of pasture processing and tackle the shortage of fodder during the dry season.

The equipment must be tailored to the tropical climate and should feature high productivity, durability, and low maintenance costs for deployment in 20 agricultural demonstration zones.

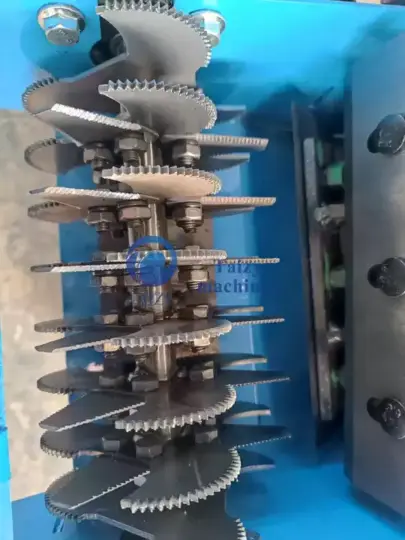

Mass production of silage chopping machine

- The factory initiates the special production line featuring manganese steel blades and a fully enclosed motor to satisfy both hardness and dustproof standards.

- With a modular assembly approach, we can complete 250 sets of equipment in just 15 days, each machine capable of processing 8-12 tons per hour. This setup is versatile enough to handle various raw materials, including corn stalks and elephant grass.

- To ensure cutting uniformity and monitor motor temperature rise, sampling equipment undergoes a rigorous 72-hour testing period. Additionally, it is run in high temperature and high humidity conditions for 48 hours to confirm stability.

- The blades are treated to be rust-proof and are individually encapsulated, while the motors and drive systems are protected with cushioning materials. Each customized wooden case is designed to be moisture-proof and damage-proof, making it ideal for sea transportation.

Machine packaging and logistics

We packed and shipped 250 units of silage chopping machines in several containers. Our technical team traveled to Uganda to help with unloading, installation, and operation training, ensuring the equipment is set for production.

This collaboration represents a significant advancement in the scale of our agricultural machinery within African government projects. We look forward to strengthening our long-term partnership in sustainable agriculture. Please reach out if you need any additional information.