Screw Peanut Sesame Oil Press Machine Oilseed Extraction Equipment

Screw Peanut Sesame Oil Press Machine Oilseed Extraction Equipment

Oil extraction equipment | Automatic oil expeller

Features at a Glance

The automatic screw oil press machine is mainly popular among self-employed and small oil press shops. The machine’s oil extraction efficiency can reach 20% to 50% of the seed weight. Compared with the traditional oil press, the oil yield can be increased by 4% to 6%, and the energy saving can be 60% with the same output.

This machine is simple, convenient, easy to operate, has high oil yield, energy saving, small footprint, and wide range of use. According to different output requirements, we have different machine models, such as 6YL-60, 6YL-70, 6YL-80, 6YL-100, 6YL-125, etc.

For screw oil pressers, we have two models, a hot press and a cold press, as well as hydraulic presses. They can meet the different needs of customers for oil pressing. They are also different in applicable materials and are highly commercial.

Hot selling screw oil press machine

The automatic screw oil press machine can realize vacuum filtration. Different temperatures can be set according to different materials.

Rotating the handle can adjust the pressure that people require to squeeze the material. The amount of oil squeezed out at a time is also different for different pressures, and the thickness of the oil cake is also different.

Nowadays, more merchants are using this machine for on-site processing in rural areas or urban areas. Using this machine seems to be more transparent in production, which makes customers more assured. It is of great benefit to the development of business. Many regions now operate according to this operating model and are very profitable.

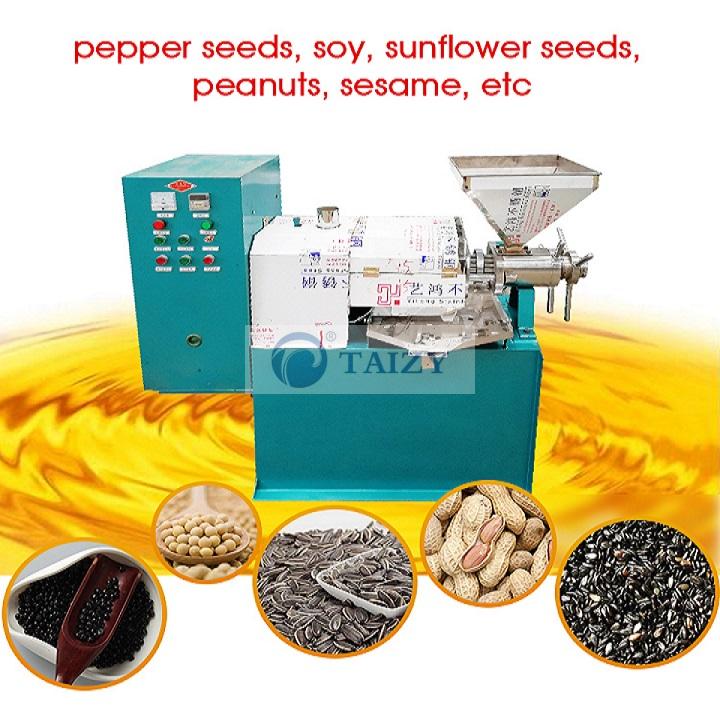

Screw oil expeller applicable materials

Peanuts, flax, sesame, rapeseed, oil sunflower, cottonseed, soybean, walnut, pepper seed, tung seed, castor, almond, etc.

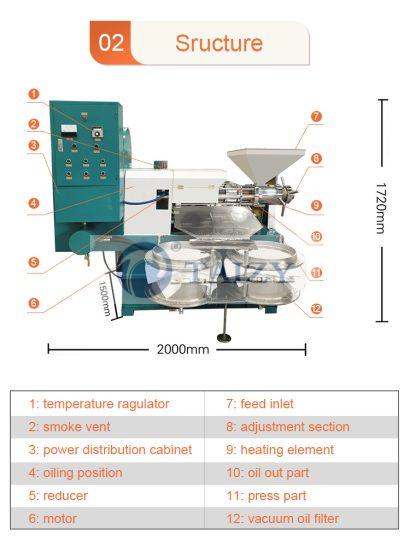

Screw press oil extraction’s structure

The structure of the screw oil press machine includes a temperature regulator, smoke vent, powder distribution cabinet, oiling position, reducer, motor, feed inlet, adjustment section, heating element, oil out part, press part, vacuum oil filter, etc.

Working principle of screw oil extractor

In a screw oil press machine, raw materials enter the press chamber from the hopper. Then, they are pushed inward by the screw for pressing.

The high pressure and friction between the material, screw, and chamber create relative movement and generate heat, aiding in the oil extraction process.

The screw’s increasing diameter and decreasing pitch push the material forward and outward. While frictional heat helps denature proteins, increase plasticity, and reduce viscosity, thereby improving the oil yield and allowing oil to flow out through gaps in the press.

Parameters of screw press oil pressor

| Model | 6YL-60 | 6YL-70 | 6YL-80 | 6YL-100 | 6YL-125 |

| Screw diameter(mm) | Φ55 | Φ65 | Φ80 | Φ100 | Φ125 |

| Screw rotating speed(r/min) | 64 | 38 | 35 | 37 | 34 |

| Main power(kw) | 2.2 | 3 | 4 | 7.5 | 15 |

| Vacuum pump power(kw) | 0.75 | 0.75 | 0.55 | 0.75 | 0.75 |

| Heating power(kw) | 0.9 | 1.8 | 2.2 | 3 | 3.75 |

| Capacity(kg/h) | 40-60 | 50-70 | 80-120 | 150-230 | 300-350 |

| Weight(kg) | 240 | 280 | 880 | 1100 | 1400 |

| Size(mm) | 1200*480*1100 | 1400*500*1200 | 1700*110*1600 | 1900*1200*1300 | 2600*1300*2300 |

Screw oilseed extraction machine advantages

- High oil output rate, compared with the old equipment, the normal oil output rate can be 2 to 3 percentage points higher, and every 100 catties of peanuts processed can increase by 2-6 catties on average.

- Energy saving, reducing electric power by 40% with the same output.

- Labor saving, the same output can save labor by 60%, and 1 to 2 people can organize production.

- Wide use. One screw oil press machine with multiple functions can squeeze more than 30 kinds of oil crops such as peanuts, flax, sesame, rapeseed, sunflower, cottonseed, and soybean.

- Pure oil. The residue is vacuum filtered to ensure the purity of the oil and meet the sanitary and quarantine standards.

- It occupies a small area. The oil mill needs 10-20 square meters to meet the needs.

- Reasonable pressing and high oil output rate. The infrared temperature control system is used to automatically control the pressing temperature and moisture. So the oil is directly softened and activated by the oil molecules, the pressing is stable, and the oil output rate is greatly improved.

- High-efficiency precision filtration is fast and convenient. Adopt various fine filter system devices to increase the oil filter pressure and increase the temperature of the crude oil.

- The new oil guiding technology, automatic filtration, pure oil, oil filtration, and pressing are carried out simultaneously, which greatly improves the oil filtration speed, is convenient and practical, and is an ideal choice for users.

Screw oil mill’s instructions for use

- Before use, you must read the instruction manual carefully and be familiar with the performance characteristics and operation methods of this screw oil press machine.

- Before starting the machine, a comprehensive inspection must be carried out. All fasteners should not be loosened, the handle can be turned flexibly, and the pulley should be turned by hand. The running parts should be normal and there should be no abnormal noise. Then add 30# oil into the reducer.

- The machine is connected to a three-phase four-wire power supply. After the power is turned on, the main shaft should rotate counterclockwise. In any case, the machine must have a good grounding device, otherwise, it cannot be turned on.

- Adjust the temperature controller to 120°C—160°C (according to the oil material), and turn on the heating switch to the heating position of the main engine to heat the machine.

- Press the button on the main motor and the main motor will start to rotate. The direction of rotation should be counterclockwise.

- After the new screw oil press machine is installed, grind for 4-8 hours. The method is to slowly feed the dried oil cake from the hopper, and repeatedly press back to polish the press chamber.

- During normal squeezing, the feed must be kept even, not too much or too little, or running idling if the material is cut off. At this time, the load of the machine is normal, the operation is stable, and the sound is rhythmic.

- Shut down. Stop feeding before shutting down, and then put in a small number of cake crumbs, wait until the remaining material in the press chamber is exhausted, and the cake outlet will no longer deliver cakes before shutting down. After stopping, turn the adjusting screw clockwise out 1-3 times, and then disconnect the power supply.

Our factory produces other kinds of oil presses, such as hydraulic oil presses(Oil Extraction Machine |Screw Oil Expeller|Hydraulic Oil Mill). If interested, you can fill in the form on the right and tell us your raw material and specific needs. We will give you the right recommendation to help your oil-pressing business run smoothly.