15TPD Upgraded Rice Processing Line Plus Color Sorting And Packaging Machines

15TPD Upgraded Rice Processing Line Plus Color Sorting And Packaging Machines

This advanced rice processing line formed by upgrading the rice milling unit plus the color sorter and packaging machine is a comprehensive solution to improve the quality and efficiency of rice processing.

The color sorter intelligently screens the rice grains through optical technology to ensure more consistent color, shape, and quality of the finished product. Finally, the packaging machine automatically packages the processed and screened rice to maintain the freshness of the product.

This production line optimizes the appearance and quality of the product, bringing a higher level of automation and standardized production to the rice processing industry.

Rice Processing Line Main Structure

Workflow Of White Rice Processing Equipment

1. Rice Mill Primary Processing Stage

Paddy is first removed from large straws and stones and then dehulled, followed by milling and secondary milling (rice whitener) and white rice grading.

2. Color Sorting Stage

The color sorter uses advanced optical technology to intelligently detect impurities and inferior particles in the rice flour. Based on the detection results, the color sorter automatically sorts out the rice grains with color differences or inferior products to ensure the color and quality of the finished products.

3. Packaging Stage

Qualified high-quality white rice is conveyed to the packing machine. The packaging machine measures and packs according to preset parameters, realizing an automated packaging process. After the finished product is packaged, it can be labeled and encapsulated and then sent to the warehouse or sent to the market.

Working Principle Of Color Sorter In Rice Processing Line

- Color Sorting is an operation that uses photoelectricity to detect and separate individuals (grains, lumps, or balls) and foreign inclusions that have abnormal color or are infested with pests and diseases from a large number of bulk products.

- The storage process, due to heat and other reasons, will make part of the rice deterioration, become yellow grain rice. Yellow grain rice contains harmful ingredients, the finished rice contains yellow grain rice not only affects the commodity value of rice, but also affects the health of consumers, and must be removed as far as possible.

- Due to the yellow grain rice and normal white rice without general physical characteristics, the difference between the yellow grain rice and white rice can only be used between the color, and reflectivity differences, with photoelectric colorimetry methods and equipment removed. The difference in color can also be used to remove foreign-colored grains such as small glass and cinders that are mixed into the rice.

Paddy Milling Unit Matching Spare Parts Show

For the rice processing line with higher working intensity, in order to better maintain the machine and lengthen its service life, the wearing parts need to be replaced regularly. Parts can be bought with discounts.

Among them, there are two kinds of polishing machines available, iron rollers and emery rollers. The difference between them is that the iron roller is suitable for round rice, and the finished product is brighter, but the rice is easy to break; the emery roller is mostly suitable for long rice, its strength is relatively small, and the rice obtained is not easy to break. It should be noted that these two rolls can be used for a longer time compared with other worn parts.

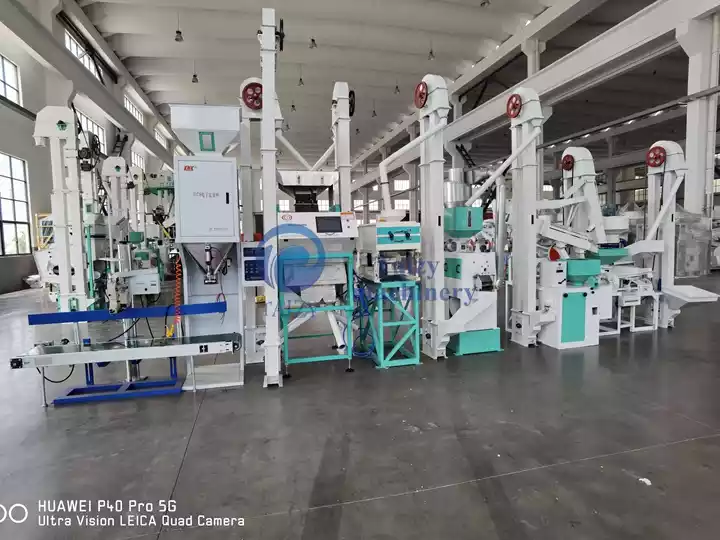

Rice Processing Line Machines Factory Display

Our factory has a stock display, welcome to visit our advanced upgraded rice milling unit production line, we look forward to cooperating with you. In addition, if you have any doubts about the machine, please feel free to contact us.