Rice Milling Plant Machine丨Automatic Rice Mill Production Line

Rice Milling Plant Machine丨Automatic Rice Mill Production Line

Auto Rice Milling Unit | Paddy Processing Plant

The rice milling plant machine unit is an efficient, economical, and easy-to-operate solution for rice processing. The equipment integrates de-hybridization, destoning, rice polishing, and grading in one unit, featuring a compact structure and a small footprint.

With a daily output of 600-800 kilograms, it can efficiently process paddy into high-quality rice that is white, free of impurities, and with a broken rice rate of less than 1%, which can be sold directly into supermarkets or food processing plants.

The production line is widely exported to Thailand, Vietnam, Nigeria, and other countries, well-received by users, and has established long-term cooperation.

It is especially suitable for small grain processing plants, rural cooperatives, and entrepreneurial projects. In addition, the whole machine is guaranteed for 2 years, which makes the use more at ease.

Complete rice milling unit advantages

- The equipment integrates multiple processes such as hulling, de-stoning, screening, polishing, etc. and is multi-purpose in one machine.

- The polishing rate is more than 80%, the broken rice rate is controlled within 1%, and the finished rice is full in appearance and good in selling.

- Equipped with vibrating screen and de-stoning device, effectively removing stones, weeds, dust and other impurities in the rice.

- The gravity sieve operates at a fast speed, with high screening precision, and the whole set of process is basically automated, saving labor cost.

- Low noise, no dust pollution in the process of rice production; low power consumption, more energy-saving operation.

- Equipped with crushing device, the rice husk can be crushed as feed, to enhance the utilization rate of resources.

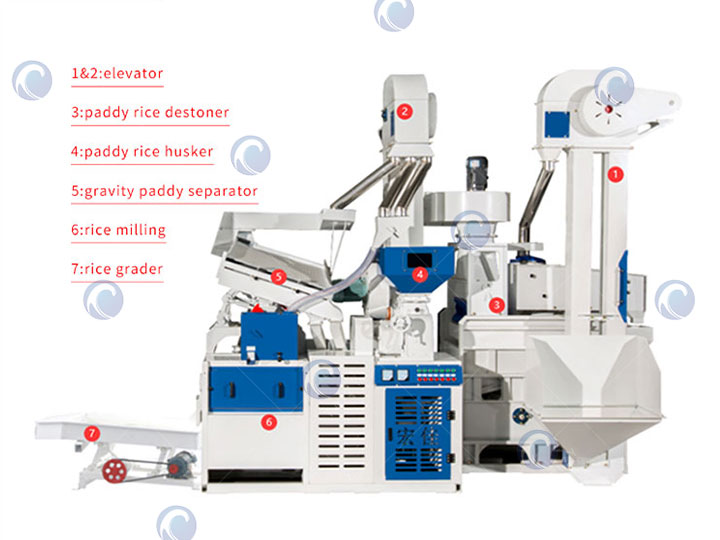

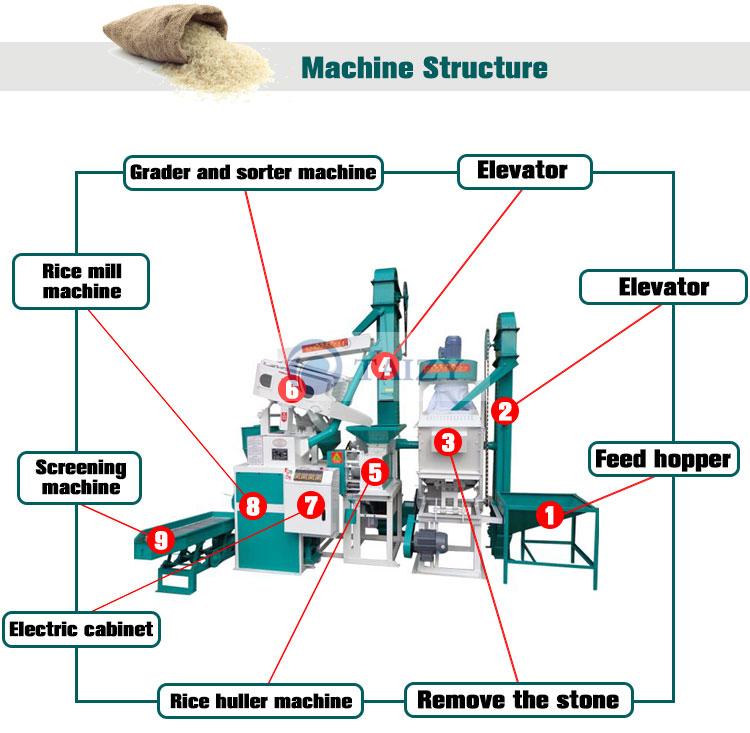

Structure of rice milling plant machine

This rice milling plant machine mainly comprises a feed hopper, rice elevator, stone removing part, rice huller part, grader and sorter machine, electric cabinet, and screening machine.

Rice huller machines technical parameters

Different sizes and volumes of production lines have different technical parameters. When purchasing, you have a variety of choices. Please consider your budget and production expectations, and so on.

| Capacity | 600-700kg/h |

| Milling rate | 71% |

| Total power(not include the crushing machine) | 19.25kw |

| Total power(not including the crushing machine) | 26.26kw |

| Dimension | 3000*2600*2900mm |

| Specification | Function |

| 1-Rice hopper | Inlet |

| 2-Single hoist | Lifting rice to suction gravity stone remover from a dust belt. |

| 3-Suction gravity stone remover | Remove stone and straw from rice. |

| 4-Automatic rice husking machine | Remove the husk from the rice and turn the rice into brown rice. |

| 5-Twin hoist | They are all contractors. Control the start of each motor. |

| 6-Gravitational sieves | Completely separate rice from brown rice. |

| 7-Power Distribution Box | They are all contractors. Control the start of each motor. |

| 8-Negative pressure rice mill | Whitening and polishing brown rice. |

| 9-Broken rice grading screen | Separating broken rice from finished rice. |

| 10-Grinder | Crushed chaff and rice bran. |

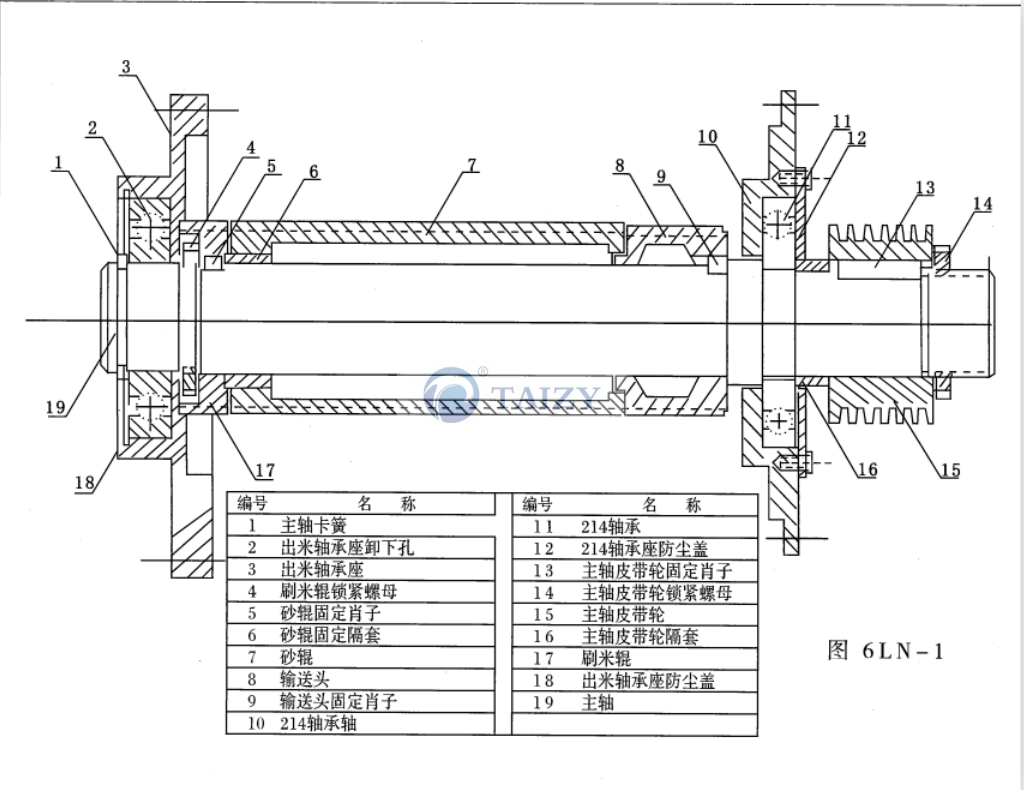

Motor model of rice huller machine

| Motor model | Matching parts of motor | |

| 0.75KW-6 level (960 RPM) | 6-Gravitational force screen(one) | 5-Twin hoist(one) |

| 1.1KW-4 level (1420 RPM) | 3-Suction gravity stone remover(Small motors for stone removal)(one) | |

| 1.1KW-2 level (2800 RPM) | 3-Suction gravity stone remover(Small motors for stone fans)(one) | |

| 22KW-4 level (1460 RPM) | If customers do not want 10 crushers. 8- negative pressure rice mill and 4- automatic rice hulling machine, they share a 15-kilowatt motor. | |

| 15KW-4 level (1460 RPM) | If customers do not want 10 crushers. 8- negative pressure rice mill and 4- automatic rice hulling machine, they share a 15-kilowatt motor. | |

| 550W-4 (1320 RPM) | 9-Broken rice grading screen (one) | |

| Total power of a machine:26.25KW(Grinder containing 10-)6 motors Fine bran type

19.25KW(10- pulverizer)6 motors Bran type | ||

| Machine length: 3.3m, width: 2.6m, height: 2.9m | ||

| The number of packages is 3. Total: 10.9 partyLength * width * high volume: 170*140*215=5.17190*98*135=2.5196*2.92*1.15=3.22The main machines are all assembled, the machine pallet is made of iron, and the four sides are hot pressing plates. Users can easily use them. |

Technical parameter

| Overall weight | 900kg |

| Dimensions | 3300x 2750 x 2800mm |

| gravity screen | 0.75KW-6 level |

| Double hoist | 0.75KW-6 level |

| suction fan of rice destoner machine | 0.75KW-2 level |

| rice destoner machine | 1.1KW-4 level |

| rice sieve (optional) | 0.37KW-4 level |

| Main unit | 15KW-4 level / 22KW-4 level (with crushing) |

Technological process of rice milling plant machine

This rice grinding machine conveys the raw materials to the milling and gravity sieving section after removing impurities through an elevator.

The husk is blown out by the fan, the brown rice is milled into white rice, and the sifter then separates the broken rice, making the whole process efficient and clean.

- Put the rice into the feeding hopper(1).

- Elevator(2) conveys the rice into the rice destoner part(3) that removes the stones contained in the rice.

- Elevator(4) conveys the rice again and then rice drops into the huller part(5), removing the husk of rice.

- Rice goes into the grader and sorter part(6), however, the rice with lightweight and bad quality will go into the rice huller part(5).

- Elevator(4) conveys this bad rice to the grader and sorter part again, which means bad quality rice will enter the rice huller part and elevator twice.

- Good rice will directly enter the rice mill part(8) to be polished.

- Polished rice enters the screening part(9) which vibrates violently to filter the broken rice and impurities again.

- Finally, you will get white rice from the outlet of the screening part.

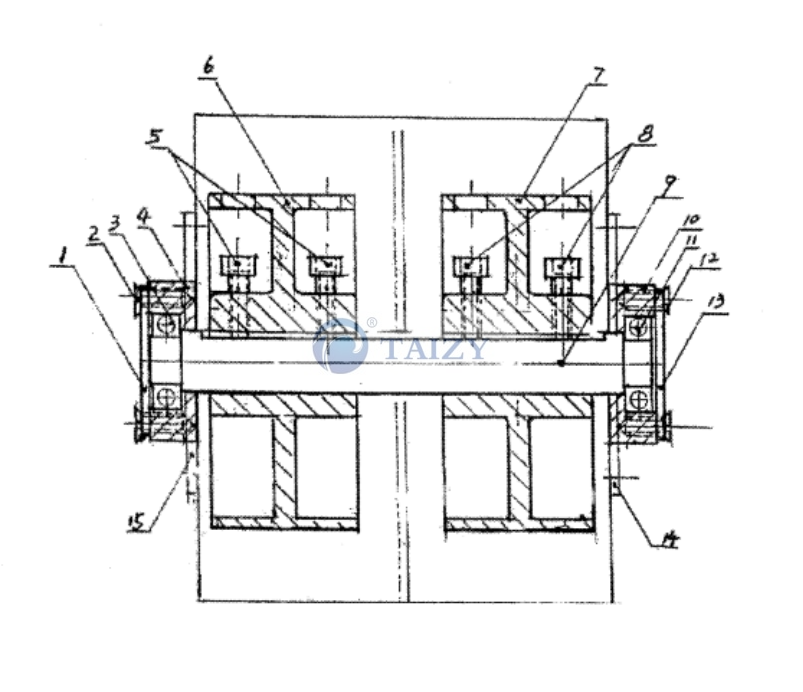

How to disassemble the lower bearing of hoist

- Lose the fixing panel of the base bearing of the single (double) hoist(14, 15).

- Remove the dust cover of bearing(1, 13) on both sides.

- Loosen the flat plate fixing the bolt.

- Use the iron to hold against the left shaft head and hit the right side.

- Remove the hoist shaft.

- The sequence of disassembling the lower bearing of the hoist.

- 15→14→2→1→12→13→5→8→9.

Note:

- When the single (double) hoist is in use, it is necessary to pay attention to the tightness of the bucket belt.

- If the hoist is easy to block or can not discharge rice, please check if the bucket belt, upper or lower base is loose.

- Then check whether the pulley fixing bolt is loose(5)and whether the iron plate at the exit of the upper seat of the hoist slides downward.

Solution:

- Tighten the belt pulley on both sides of the hoist to tension the bucket belt.

- Tighten the fixed bolt of the belt pulley of the upper and lower hoist.

- Open the cover of the upper part of the hoist and push the iron plate at the exit upwards, then lock it. (The distance that the iron plate pushes upwards should be based on the standard that the bucket belt does not hit the iron plate.)

- After the hoist is blocked, there is a gate on the left or right side of the lower seat of the hoist, which can be used to pull out the impurities in the hoist through the gate.

Successful cases of commercial rice mill machine

We exported 5 sets of rice milling plant machines to Nigeria last year, and the customer feedback is good, and plans to continue purchasing.

A customer from the UK enquired about setting up a small-scale rice milling plant machine through our website.

After communicating with the sales manager via WhatsApp, we recommended a 20-ton capacity rice milling production line for him, and the order was finally placed successfully. The equipment has been packed and shipped.

FAQ

How many types of combined rice milling production lines do you have?

As for this series, we have more than 10 types, and each type adds some part to the base of this one.

What is the biggest capacity of this series of rice milling plant machines?

The biggest capacity is 100Ton/Day.

What is the difference between this big-size rice milling machine and other types?

This rice milling plant machine has a lifter, stone removing part, crushing part, and screening part, which are not included in the normal rice milling plant machines.

Is it easy to install and disassemble the machine?

Yes, we can arrange for our technician to help you install it if necessary.

What is the broken rate?

The break rate of rice is less than 1%.

We have different models of rice milling production lines from 15 to 60 tons. Customers can choose according to their needs. In addition, we also have rice and wheat threshing machines, which can first thresh the rice and then use the rice mill for deep processing.

If you are interested in our rice milling plant machines or would like to know more detailed information, please feel free to contact us for a full range of services. You are warmly welcome to visit our factory and experience the excellent performance of the rice milling unit for yourself.