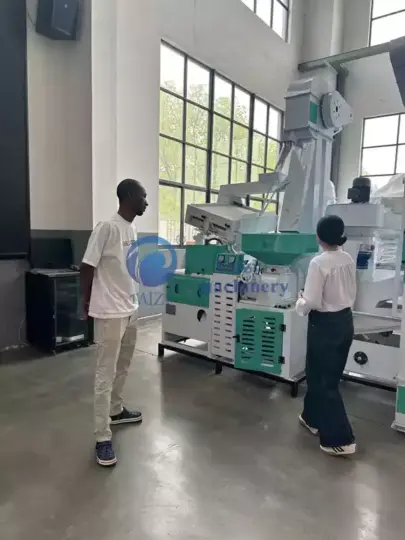

Last month, a customer from Mali arrived at our factory, led by the sales manager and the technical team, to start a visit to the deep rice mill unit (rice finishing equipment) to fully verify the performance of the equipment.

Background information of the customer

The customer is engaged in the field of paddy purchase, hulling and polishing as well as distribution of refined rice, with an annual processing capacity of over 8,000 tons of paddy, covering the staple food consumption of local residents and the export market of neighboring countries.

The customer wants to break through the current bottleneck of low processing precision and high broken rice rate (about 12%), and at the same time reduce the operation and maintenance cost through localized equipment procurement, so as to reduce the dependence on imported polished rice.

Rice mill unit factory visit

Mali customers, accompanied by managers and engineers, visited the rice mill unit production line and discussed technical details about the characteristics of African rice varieties.

- On-site demonstration of the whole process from de-stoning, de-hulling to polishing and grading of rice, the customer personally operates the equipment and tests the processing effect.

- For Mali’s high humidity environment and the characteristics of many varieties of rice, we explained the moisture-proof design of the equipment and the flexible adjustment of parameters.

- The customer’s technical team participated in the disassembly simulation of the equipment and mastered the daily maintenance and troubleshooting skills.

Why choose our rice milling machines?

- Our equipment adopts multi-stage flexible milling technology, which reduces the broken rice rate to less than 5% and increases the rice yield to more than 70%.

- Equipped with humidity sensing and pressure adaptive system, it can automatically adapt to different varieties of rice.

- Factory direct supply, the whole line packaged and shipped, the cost is more controllable and the parts are more timely.

- This set of rice milling unit is suitable for both small batch and batch production, easily adapted to rural cooperatives, regional processing points, and urban grain and oil enterprises.

- We provide the whole line of equipment installation and debugging, operation training, and one-year warranty and lifelong maintenance; we can send field engineers according to customer needs.

Our factory specializes in manufacturing rice mill unit machines with different outputs from 15-100 tons per day, and there is always a suitable one for your production scale. Feel free to fill in the form on the right to make a consultation.