15TPD Rice Mill Production Line With Polisher And White Rice Grader

15TPD Rice Mill Production Line With Polisher And White Rice Grader

This rice mill production line begins with the standard 15TPD rice milling unit, whose main task is to hull, peel, and mill the grains to convert them into regular white rice.

Next, the polishing machine comes into play, removing a layer of outer skin from the surface of the white rice by friction, making the grains smoother and enhancing the overall appearance and taste.

Subsequently, the white rice grading machine accurately grades the rice according to the size and shape of the grains. This helps maintain product consistency and quality, ensuring that each bag of rice is of uniform quality and meets market demand.

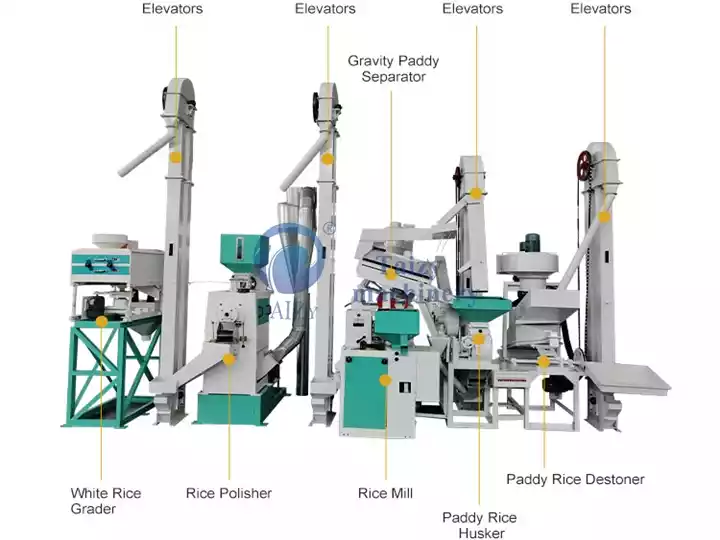

Rice Mill Production Line Main Structure

Principle Of The Rice Polishing Machine

- This equipment is mainly through the slight friction to adhere to the white rice surface on the chaff powder erased, to ensure that the white rice is clean, improve the appearance of the finished product and color, but also conducive to the rice storage and recycling of rice bran, but also to make the subsequent white rice grading equipment is not easy to block the work surface, to ensure that the grading effect.

- Rub rice process, because the white rice grain strength is low, so it should be slow and not strong, to prevent producing too much broken rice. The white rice out of the machine after rubbing the rice, produce the broken rice can’t be more than 1%, contain chaff quantity can’t be more than 0.1%.

Role Of The White Rice Grader

- Countries around the world take broken rice as an important index to distinguish the grade of rice. So white rice grading is in order to adapt to the international special requirements of rice quality (generally according to how much rice contains broken rice graded and set up a process).

- Rice with the same precision often has a huge price difference because of the difference in broken rice. Containing less broken rice than containing more broken rice price is much higher, and the quality of steamed rice is also much better, so try to reduce the rate of broken rice in the rice mill production line.

- White rice grading equipment used: flat rotary sieve, drum selector, and so on. Through the processing of white rice grading sieve, it can be divided into small broken rice, large broken rice, and finished rice, and then processed according to the required grade standard.

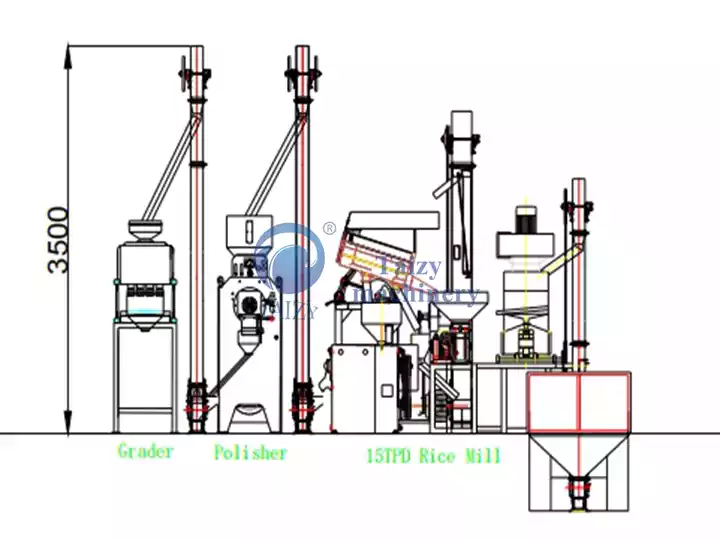

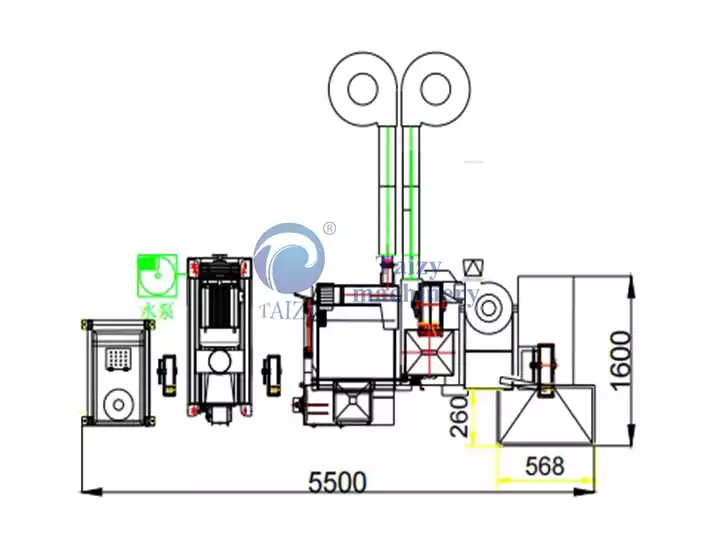

Workflow Of Paddy Processing Equipment

An advanced automatic control system manages the entire rice mill production line. This not only improves production efficiency but also ensures precise control of each step.

1. Standard Rice Milling Unit

This set of equipment is the core of this whole rice mill production line, integrating hulling, peeling, and milling, which can efficiently transform grains into edible white rice.

2. Rice Polisher

Adopting advanced surface treatment technology, this machine removes the outer skin of white rice by friction, making the grains smoother. This step not only enhances the appearance of the rice but also improves the taste, providing more choices for the high-end market.

3. White Rice Grader

In this area, there are two layers of sieves that categorize the rice into three levels: intact large grains, intact small grains, and broken rice. This allows us to grade the rice according to size and shape, ensuring that each bag of rice has uniform quality.

Rice Milling Plant Installation

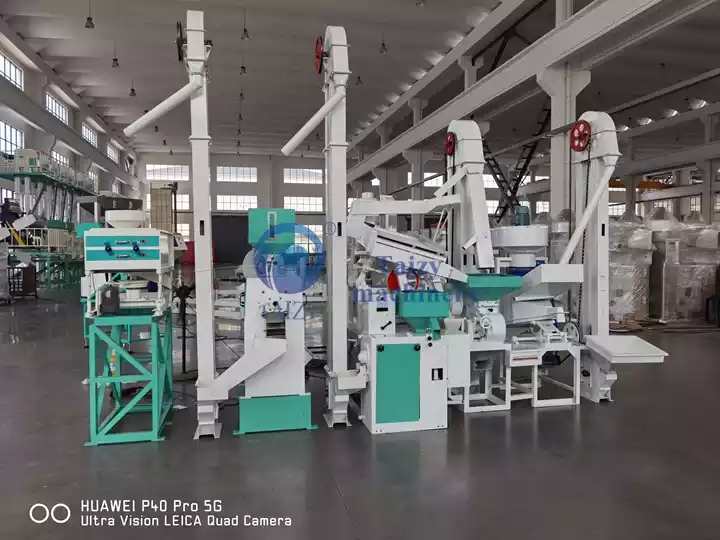

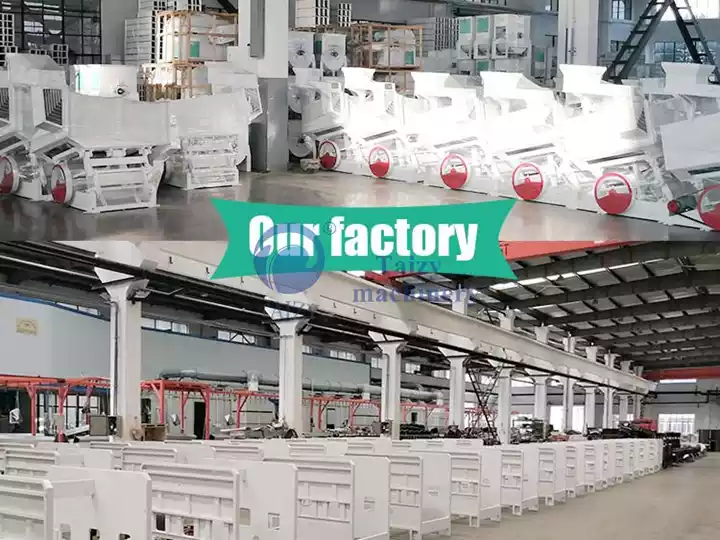

Taizy Factory Machines Display

Welcome to visit our rice milling unit production line factory machine display, our factory display of efficient, advanced rice processing equipment.

You are welcome to visit our factory anytime, to experience the efficient operation of the rice milling unit production line and the charm of advanced technology, which can give you a deeper understanding of our production process and technological innovation.