Two Models Of Potato Harvester Machine For Sale

Two Models Of Potato Harvester Machine For Sale

Potato Digger | Potato Harvesting Equipment

Features at a Glance

The potato harvester is mainly used to complete the harvest of underground potatoes, which includes potatoes, sweet potatoes, carrots, etc. It is suitable for various soil types: sandy soil, loamy soil, and medium cohesive soil.

The machine can turn the fruit out of the soil and form a pile, reducing manpower consumption and facilitating people to pick it up. Due to the large digging depth, it will not cause damage to the potatoes.

This machine is popular in many countries, including the Netherlands, the United States, Canada, Germany, France, Russia, etc. (Why Automatic Potato Harvesting Machines Are Popular In Canadian Countries). Here are various working scenarios.

Introduction about our potato harvester

The harvester machine can help people harvest the crop efficiently. Our potato harvester equipment is specially designed according to our country’s characteristics of potato planting. The yield that the machine can harvest is more than a dozen people can harvest.

The whole operation process is smooth. The machine is convenient to connect and operate. It is flexible, practical, high in harvesting efficiency, low in buried potatoes, and it does no damage to potatoes.

The machine can turn over the soil. The remaining agricultural film is turned directly on the ground, which is more convenient to clean up. It is also conducive to the growth of the next season’s crops. So our potato reaping machine is favored by users everywhere.

Working principle of potato digger

- Before working, connect the machine to the tractor. Different potato harvesters need to match with tractors of different horsepower.

- When the tractor starts to move forward, the potato-reaping machine should start to work together.

- The working principle is that under the PTO drive of the tractor, the soil and tubers are separated by the vibration of the vibrating screen. The soil falls in the gap of the vibrating screen, and the potatoes remain on the screen.

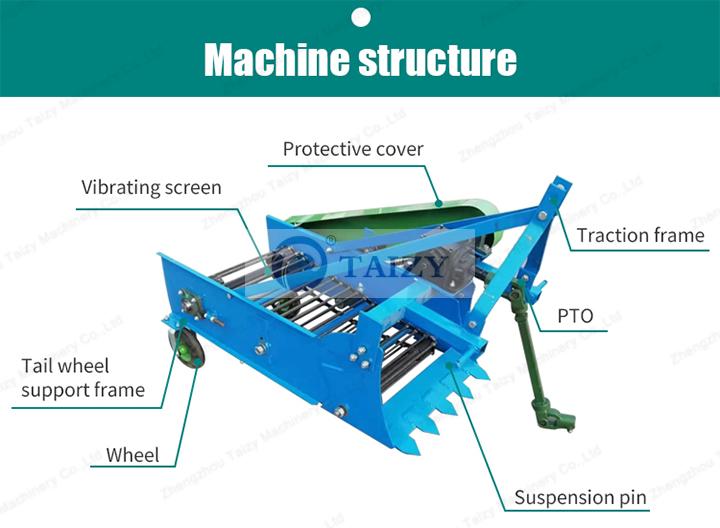

Potato harvesting machine’s main structure

The potato harvester includes several parts: wheel, tail wheel support frame, vibrating screen, protective cover, traction frame, PTO, and suspension pin. You can find more details in the below picture.

Technical parameters

We have two models of potato harvester: single-row and two-row potato harvesting machines. You can get detailed information from the sheet. For more details, you can consult our staff.

| Model | 4U-1 | 4U-2 |

| Harvesting rows | 1 | 2 |

| Width of cut(mm) | 600 | 900/1300/1600/1800 |

| Depth of cut(mm) | 100-250 | 100-250 |

| PTO rotation speed(r/min) | 540-720 | 540-720 |

| Weight(kg) | 160 | 260/335/390/440 |

| Tractor power(hp) | 20-30 | 40/50/70/80 |

| Mounted cat | three-point suspension Cat Ⅱ | three-point suspension Cat Ⅱ |

Preparation before work

- Disassemble and clean the various parts of the potato harvester in advance, and apply grease to the bearing parts during the cleaning process to ensure the normal operation of the bearing.

- When working in the ground, it is necessary to ensure that there are no big rocks, obvious stones, etc. The aim is to ensure that the potato digger will not cause damage to the gears and blades due to the rocks.

Advantages of the harvester

- Highly efficient, this machine can harvest approximately 0.27 hectares per hour and has a feed capacity of around 180 kg/s.

- The potato harvester leaks soil quickly, and it does not cause any damage to the potato epidermis. The auxiliary storage is neat, and the potato harvest rate is high.

- The residual film is recovered cleanly, and the machine can complete the digging of potatoes efficiently and quickly at one time.

- The conveyor chain adopts a special design and is durable.

- It takes a frame structure, so the potato harvester is light, durable, and more convenient to install.

- The overall design follows the principle of mechanics after long-term repeated experiments. It has wide adaptability, high work efficiency, low demand power, fast recovery, and adapts to various soils.

Technical maintenance and storage

- After the end of each shift, the soil in each part of the machine should be removed.

- Check the fasteners of various parts, and tighten them in time if they are loose.

- Check whether the rotating parts are flexible. If they are not normal, you should adjust and eliminate them in time.

- When the machine has not been used for a long time, attention should be paid to prevent rain and avoid contact with acidic substances to avoid corrosion. The blades should be treated with oil.

If you are interested in our advanced potato harvester, please feel free to contact our professional team for more details and customization options. We look forward to hearing from you and providing you with the most suitable solution.