A rice miller is used to remove the brown outer skin (rice bran) from the inside. Why add 2 rice mills or 3 rice mills when you can get white rice with 1 rice mill? This may be your confusion. The main reasons involve production efficiency, improvement of rice quality, and adaptability to the characteristics of different grains.

3 Rice Millers to Improve Work Efficiency

If we put the same amount of rice into 1 rice mill, to become good rice, it must grind and rub the rice for a long time and then come out, but other machines cannot work, so the efficiency is very slow. If we put the same amount of rice into 3 rice mills and work them continuously, the rice will come out of each rice mill quickly.

Reduce the Rice Breakage Rate

When using a rice miller, the pressure of the rice roller must be very high, so that you can get white rice, but it is easy to break the rice. By using multiple rice mills in a production line, the shape and texture of the rice grains can be optimized at different stages, improving the quality of the finished rice.

Improve Whiteness and Cleanliness

If you only use one rice milling machine, the brown rice husks will be mixed with the white rice, and the brown rice may not be clean, but with three rice mills, small impurities can be removed very cleanly.

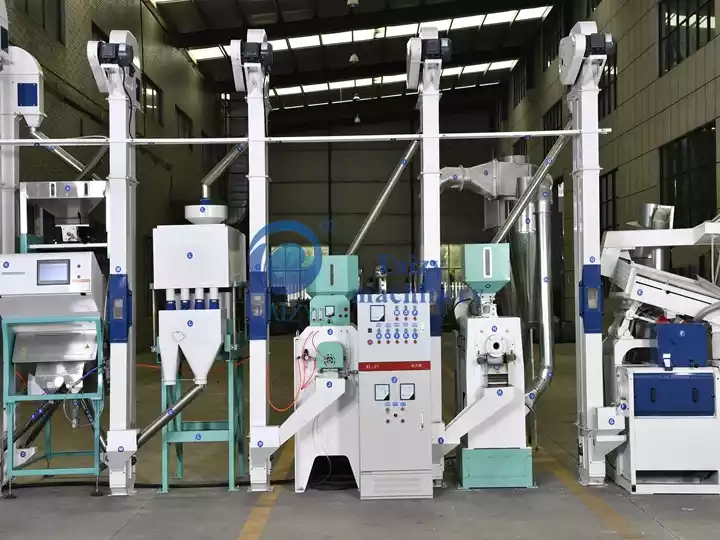

Finally, using multiple rice millers in a production line can provide failover. If one rice mill breaks down, other machines can continue to work, reducing the risk of production line stagnation. Therefore, the larger the production line, the more rice mills there are on the production line.