Horizontal TMR Feed Mixer for Sale | Mash Forage Mixing Machine

Horizontal TMR Feed Mixer for Sale | Mash Forage Mixing Machine

Silage feed mixer | Feed mixing machine

The horizontal TMR feed mixer is a blending device specifically designed for modern ranches and feed mills, integrating three key functions: grinding, stirring, and mixing.

It can process 3 to 10 tons of silage and roughage feedstock per hour, simultaneously blending roughage, concentrate feed, and various nutritional additives (such as minerals and vitamins) to achieve scientifically balanced total mixed rations.

Featuring a dual-spiral cutting and mixing system, it achieves over 95% uniformity in mixing, effectively increasing cattle and sheep feed intake by 20% and reducing feeding costs by 15%. This makes it an ideal solution for enhancing profitability in modern livestock operations.

Horizontal forage feed mixer advantages

- High-strength durable structure: features high-alloy steel cutting blades that are wear-resistant and impact-resistant, ensuring a stable structure, smooth operation, and extended service life.

- High-efficiency dual-speed drive system: independent dual-speed transmission for cutting and mixing boosts efficiency by 40%, significantly reducing labor and time costs.

- Intelligent precision mixing: automatic feeding and optimized discharge system achieve ≥95% mixing uniformity, ensuring precise and consistent feed nutrient ratios.

- Easy maintenance, low cost: modular design for easy disassembly and inspection; dual hydraulic and mechanical drive system minimizes failure rates, shortening maintenance cycles by 30%.

- Wide applicability: processes diverse coarse feeds like corn stalks, pasture grass, and silage, while directly incorporating additives without damaging fiber structure.

- Flexible customization: tailor capacity, feeding methods, discharge configurations, and power sources (electric motor or diesel engine) to suit ranch scale and operational needs.

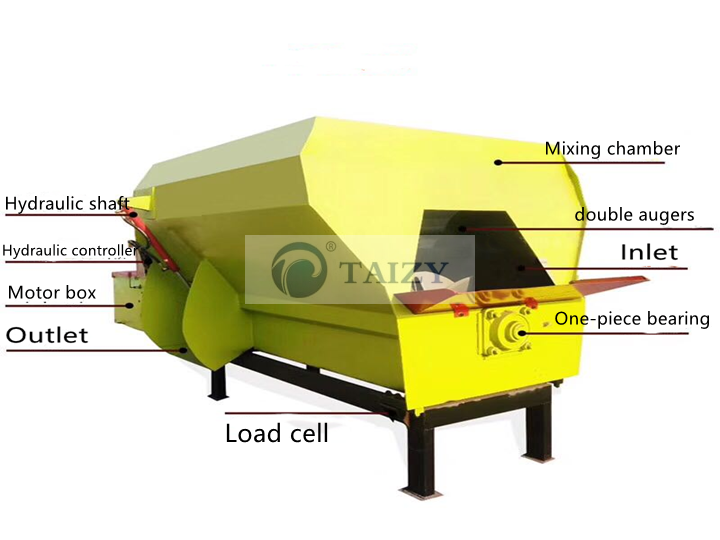

Structure of TMR feed mixer

The feed mixer contains several parts. You can get more information from the below picture.

Internal system

The internal system of the horizontal feed mixer primarily consists of three augers: one main auger and two auxiliary augers located above it.

After cutting the corn stalks with a corn stalk reaping machine, you can feed them into the horizontal feed mixer. Inside the mixer, the materials are rotated and stirred from both ends toward the center.

The blades then cut and mix the different fibrous forages and straws as they move through. This process helps to effectively pulverize and blend the total mixed ration for feeding.

Discharge system

The discharge gate control system includes a hydraulic cylinder, a fixed support, a linkage support, and a sliding discharge baffle.

The sliding baffle for discharging is mounted on the reciprocating shaft of the hydraulic oil cylinder, allowing it to either open for discharge or close to acting as a stopper. The outlet can be positioned on either the left or right side based on the user’s requirements.

Feed adding system

The machine features an advanced grass-feeding mechanism along with a unique grass-feeding roller device. It provides automatic feeding, ensures smooth grass-feeding, and boasts high production efficiency.

Weighing and measuring system

The system consists of four bridge-type load-bearing sensors along with a load-bearing display controller. It operates on a 220V power source, which transmits signals to the weighing display via a four-directional bridge weighing sensor.

The primary purpose is to show gross weight, net weight, peak value, and net weight. Additionally, the weighing and measuring system is equipped with an overload alarm function.

Silage mixing machine working principle

- During operation, corn stalks, silage, concentrate feed, and additives are fed into the hopper in specified proportions.

- The equipment automatically grabs and loosens the raw materials through the feed inlet. Inside, a high-speed rotating spiral blade roller shreds coarse fibers, controlling material length to ≤5cm to facilitate uniform mixing.

- Subsequently, spiral mixing blades alternately rotate in forward and reverse directions to compress, shear, and tumble the material, ensuring thorough penetration and integration of moisture and nutrients.

- Upon completion of mixing, the hydraulic system or electrically controlled discharge gate rapidly expels the finished feed. This product is ready for direct feeding or storage, enabling highly efficient continuous operation.

Parameters of silage feed mixer

We offer three types of feed mixers. You can find detailed information in the sheet below.

| Model | / | TMR-5 | TMR-9 | TMR-12 |

| Dimension | mm | 3930*1850*2260 | 4820*2130*2480 | 5.6*2.4*2.5 |

| Weight | kg | 1600 | 3300 | 4500 |

| Rotating speed of the auger | R/min | 23.5 | 23.5 | 23.5 |

| Volume of the mixing chamber | cubic meter | 5 | 9 | 12 |

| Structure type | / | fixed | fixed | mobile |

| Supporting power range | kw | 11—15 | 22—30 | 50-75 |

| Supporting power form | / | Electric motor | Electric motor | Electric motor |

In summary, our silage mixer serves as a valuable tool to enhance feed quality, reduce farming expenses, and support healthy animal growth. Whether you run a large ranch or a small family farm, feel free to reach out to us, and we will work together to find the right solution for your equipment needs.