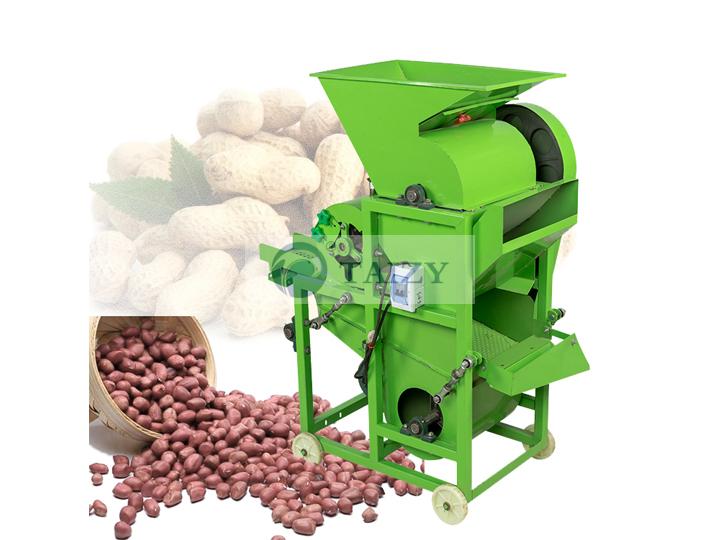

बिक्री के लिए मूंगफली छीलने की मशीन भुनी हुई मूंगफली त्वचा हटानेवाला

बिक्री के लिए मूंगफली छीलने की मशीन भुनी हुई मूंगफली त्वचा हटानेवाला

मूंगफली का छिलका हटाने वाली मशीन | मूंगफली छीलने की मशीन

विशेषताएं एक नज़र में

The मूंगफली छीलने की मशीन विशेष रूप से भुनी हुई मूंगफली को छीलने के लिए डिज़ाइन किया गया है। यह मशीन विभेदक रोलिंग घर्षण संचरण के सिद्धांत को अपनाती है। यह मूंगफली के दानों को कोई नुकसान पहुंचाए बिना लाल बाहरी त्वचा को स्वचालित रूप से हटा सकता है।

हमारा कारखाना पसंद के लिए भुनी हुई मूंगफली की लाल त्वचा छीलने वाली मशीनों के विभिन्न मॉडलों को संसाधित करता है, जिनका आउटपुट 200-1000 किग्रा/घंटा तक होता है। मूंगफली की छिलने की दर 98% जितनी अधिक है, और गिरी क्षति दर 2% से कम है।

यह मूंगफली छीलने की मशीन व्यापक रूप से तली हुई मूंगफली, बहु-स्वाद वाली मूंगफली, मूंगफली का दूध, मूंगफली प्रोटीन पाउडर, मूंगफली कैंडी, मूंगफली भंगुर, मूंगफली केक, मूंगफली का मक्खन और डिब्बाबंद उत्पादों के उत्पादन में उपयोग की जाती है।

कच्चे माल के लिए आवश्यकताएँ

- तलने/भुनने के बाद कच्चे माल की नमी की मात्रा लगभग 4% होती है।

- कच्चे माल को ओवन से बाहर निकालने के बाद, तापमान बहुत अधिक होता है, जो छीलने के प्रभाव को प्रभावित करेगा और मशीन को नुकसान पहुंचाएगा।

- मशीन को नुकसान से बचाने के लिए जिन कच्चे माल को छीलने की आवश्यकता होती है उनमें लोहे का बुरादा और पत्थर जैसी अशुद्धियाँ नहीं होनी चाहिए।

मूंगफली को छीलने से पहले आमतौर पर मूंगफली भूनने वाली मशीन के साथ उपयोग किया जाता है, जिसे हम भी प्रदान कर सकते हैं। अधिक जानकारी के लिए कृपया क्लिक करें बिक्री के लिए इलेक्ट्रिक और गैस मूंगफली भूनने की मशीन मूंगफली भुनने की मशीन.

वायरिंग एवं संचालन विधि

- वोल्टेज: 380V, 3चरण, 50 हर्ट्ज।

- मशीन के पीछे हॉपर से वायरिंग के बाद एक स्विच होता है। वायरिंग के लिए स्विच चालू करें.

- मशीन को स्थिर रूप से समतल रखें और पंखे के मुँह पर एक चमड़े का बैग रखें।

- मशीन शुरू करने से पहले, जांच लें कि क्या बिजली लाइन सामान्य है, क्या घटक ढीले हैं, और क्या परीक्षण संचालन सामान्य है।

- सुनिश्चित करें कि मुख्य इकाई और पंखा आगे की ओर घूम रहे हैं।

मुख्य संरचना और कार्य

इस इकाई में मूंगफली छीलने की मशीन और त्वचा भंडारण उपकरण शामिल हैं:

- छीलने वाली मशीन का उपयोग विभिन्न विशिष्टताओं की मूंगफली की लाल त्वचा को हटाने के लिए किया जाता है।

- त्वचा भंडारण उपकरण का उपयोग पंखे के माध्यम से छिलके वाली मूंगफली की खाल को त्वचा की थैली में अवशोषित करने के लिए किया जाता है।

मुख्य समारोह:

रोलर रगड़ संरचना को अपनाते हुए, सूखी मूंगफली गिरी हॉपर के माध्यम से मुख्य मशीन में प्रवेश करती है। लाल कोट की त्वचा को उच्च गति से घूमने वाले रगड़ने वाले रोलर द्वारा हटा दिया जाता है और पंखे द्वारा चूस लिया जाता है, और छीलने के बाद मूंगफली की सफेद गिरी को सामने के सामग्री बंदरगाह के माध्यम से छुट्टी दे दी जाती है।

मूंगफली छीलने की मशीन का संचालन

मशीन शुरू करने से पहले जांच लें कि पावर सर्किट सामान्य है या नहीं और टेस्ट ऑपरेशन सामान्य है या नहीं।

सबसे पहले मूंगफली छीलने की मशीन चालू करें, फिर ठंडी पकी हुई मूंगफली डालें।

डिस्चार्ज प्लेट को ऊपर उठाने और मूंगफली के तेजी से बहिर्वाह को धीमा करने के लिए पीलर मशीन की डिस्चार्ज प्लेट रॉड को दाईं ओर घुमाएं।

कम आधे दाने की दर और उच्च छीलने की दर के साथ डिस्चार्ज प्लेट को न्यूनतम ऊंचाई पर पुनः समायोजित करें।

मूंगफली के छिलके हटाने के फायदे

- स्ट्रिपिंग दर 98% जितनी अधिक है और क्रशिंग दर कम है।

- मशीन आकार में छोटी है और स्थापित करने और संचालित करने में आसान है।

- मूंगफली गिरी और लाल छिलका स्वचालित रूप से अलग हो जाते हैं, इकट्ठा करना आसान होता है।

- लाल त्वचा को पवन मशीन द्वारा एकत्र किया जाता है, जो फार्मास्यूटिकल्स जैसे अन्य उपयोगों के लिए सुविधाजनक है।

मूंगफली का छिलका हटाने वाली मशीन के पैरामीटर

| नमूना | क्षमता | पैरामीटर |

| एचटी-1 | 200-250 किग्रा/घंटा | मोटर शक्ति: 0.55kw पंखे की शक्ति: 0.37kw वोल्टेज: 380V/220V आवृत्ति: 50HZ वजन: 110 किलो छीलने की दर: ≥98% आकार: 1200*500*1200मिमी |

| एचटी-2 | 400-500 किग्रा/घंटा | मोटर शक्ति: 0.55kw*2 पंखे की शक्ति: 0.55kw वोल्टेज: 380V/220V आवृत्ति: 50HZ वजन: 200 किलो छीलने की दर: ≥98% आकार: 1200*750*1200मिमी |

| एचटी-3 | 600-750 किग्रा/घंटा | मोटर शक्ति: 0.55kw*3 पंखे की शक्ति: 0.75kw वोल्टेज: 380V/220V आवृत्ति: 50HZ वज़न: 280 किग्रा छीलने की दर: ≥98% आकार: 1200*1050*1200मिमी |

| एचटी-4 | 800-1000 किग्रा/घंटा | मोटर शक्ति: 0.55kw*4 पंखे की शक्ति: 1.5 किलोवाट वोल्टेज: 380V/220V आवृत्ति: 50HZ वज़न: 360 किग्रा छीलने की दर: ≥98% आकार: 1200*1400*1200मिमी |

मशीन रखरखाव और मरम्मत

- काम पूरा होने के बाद रेत रोलर के अवशेष को ब्रश से हटा देना चाहिए और स्टोरेज बैग (बॉक्स) के टूटे हुए चमड़े के मलबे को साफ करना चाहिए।

- सैंडिंग रोलर को नियमित रूप से साफ करें।

- पंखे की बाल्टी में मूंगफली और दानों को हर दिन साफ करें, और कणों को बाहर निकालने के लिए मशीन के निचले सिरे पर स्लाइडिंग दरवाजा खोलें।

- यदि एकल रेत नहीं मुड़ती है, तो कृपया बेल्ट को बदल दें।

- पंखे के प्ररित करनेवाला (प्ररित करनेवाला पर मूंगफली का पाउडर और टूटी हुई त्वचा) को नियमित रूप से साफ करें।

आप निःशुल्क निर्देश के साथ टैज़ी मशीनरी मैन्युफैक्चरिंग सप्लायर से फ़ैक्टरी-मूल्य वाली मूंगफली छीलने की मशीन खरीद सकते हैं। हमने स्पेन, वियतनाम, कैमरून, केन्या, ईरान, कांगो, तंजानिया, बोलीविया, श्रीलंका, नाइजीरिया और मिस्र को कम कीमत पर मशीनें भेजी हैं। आप दाईं ओर दिए गए संदेश फ़ॉर्म के माध्यम से हमें अपनी विशिष्ट ज़रूरतें भेज सकते हैं, और उम्मीद है, हम आपको आपकी मूंगफली प्रसंस्करण परियोजना के लिए सही उपकरण प्रदान कर सकते हैं।