Corn Wheat Millet Sorghum Grain Dryer China Supply

Corn Wheat Millet Sorghum Grain Dryer China Supply

Continuous Flow Grain Dryer | Mobile Grain Drying Machine

The grain dryer is a highly efficient and energy-saving hot air drying equipment, equipped with a rotary heating device. It is able to produce a large amount of hot air in a short time, realizing uniform drying and insecticidal treatment for many kinds of grain crops such as corn, wheat, sorghum, and so on.

It is an important mechanical equipment for preventing grain mold, improving storage quality, and achieving economic benefits. It is widely used in family farms, grain stores, cooperatives, and agricultural processing enterprises.

Grain dryer’s main application

This grain dryer machine is suitable for the drying treatment of many kinds of grain crops, including but not limited to:

- Corn, wheat, rice, soybeans, sorghum

- Millet, oats, barley, peas

- Rapeseed, peanuts and other types of seed crops

Whether it is grain with high moisture content at the beginning of harvest or seeds that need to be preserved for a long time, this equipment can operate stably and ensure the drying effect.

Tower dryer machine main specification

| Model | 5H-15 | 5H-32 |

| Capacity | 15-20 ton/batch (depending on different grains) | 25-35 ton/batch (depending on different grains) |

| Weight | 3200kg | 7500kg |

| L4288*W2738*H9871mm | L4790*W5100*H11460mm | |

| Installation size | L5000*W5000*H1170mm | L5500*W7000*H13500mm |

| Shipping | 40HQ | 40HQ+20GP |

| Power | Total 6.5kw Elevator motor 1.5kw Feeding wheel motor 0.2kw Rotary wheel motor 0.55kw Exhaust Fan 4kw Dust removal motor 0.25kw | Total 14.15 kw Elevator motor 4kw Feeding wheel motor 0.4kw Rotary wheel motor 1.5kw Exhaust Fan 4kw*2pcs Dust removal motor 0.25kw |

| Fuel and Consumption | Coal, Charcoal, or other biomass about 40kg/h Diesel about 17L/H Gas about 17CBM/h Electrical heating power 160kw | Coal, Charcoal or other biomass about 80kg/h Diesel about 34L/h Gas about 34CBM/h Electrical heating power 300kw |

| Grains input time | Around 63 minutes | Around 69 minutes |

| Grains output time | Around 58 minutes | Around 64 minutes |

| Drying time | For example, normally, the best humidity of the paddy rice for milling should be 14.5%, and drying time depends on the humidity before drying. If the rice humidity before drying is 24%, reducing the humidity of rice from 24% to 14.5%, the humidity can decrease by around 1% per hour. It takes about 10 hours. Inputting the rice to the dryer needs about 1h, outputting the rice from the dryer takes about 1h, total cycle needs about 12hours. | |

| Drying temperature | Rice or wheat ,around 55℃ Corn 85-90℃ | |

Mobile-type grain drying machine

We also have mobile dryers available, which are portable units that can be moved around from site to site for ease of use in agricultural production.

Mobile grain dryer technical parameters

| Silo Volume | Overall Size (L*W*H) mm | Weight (Ton) | Screw Conveyor Power | Main Fan Power | Induced Draft Fan | Shipping |

| 2Ton | 4000*1800* 3800 | 2.8 | 4KW | 3KW | 0.75KW | 20GP |

| 4Ton | 4200*2200* 4600 | 4.5 | 7.5KW | 5.5KW | 0.75KW | 40HQ |

| 6Ton | 4600*2400* 5000 | 5.3 | 7.5KW | 7.5KW | 0.75KW | 40HQ |

| 8Ton | 4800*2400* 5600 | 6.5 | 7.5KW | 7.5KW | 0.75KW | 40HQ |

| 10Ton | 4800*2500* 6200 | 7.4 | 7.5KW | 11KW | 1.5KW | 40HQ |

Recommend drying temperature

| Grain | Drying Temperature |

| Corn | 100-140℃ |

| Wheat | 80–90℃ |

| Rice | 60-70℃ |

| Sorghum | 100-140℃ |

| Beans | 100℃ |

| Millet | 80℃ |

| Rapeseed | 100℃ |

Advantages of cereal dryer

- Strong adaptability: it is suitable for a variety of grain and seed materials to meet diversified needs.

- Uniform drying, low crushing rate: unique S-shaped falling path design, so that the grain is heated uniformly, low-temperature and long-time drying, reducing the crushing rate and improving the quality of finished products.

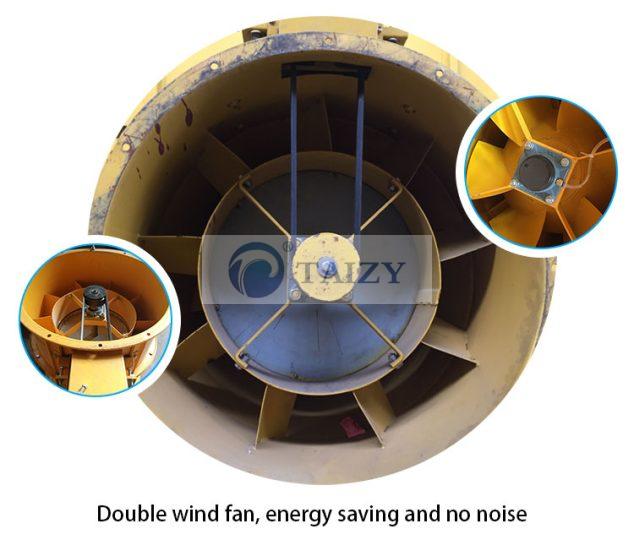

- Low energy consumption, high thermal efficiency: adopting constant temperature and low temperature drying, avoiding secondary pollution and saving fuel cost.

- Stable performance, mold and moisture prevention: consistent humidity in the drying room, effectively preventing moldy grain and prolonging storage time.

- Sturdy structure, long service life: the main parts are made of thickened stainless steel, wear-resistant and rust-proof, and the grain flows smoothly.

- Low drying cost: adopting mixed-flow design with angled air inlet, smooth ventilation, no need for frequent cleaning, saving maintenance cost.

- Environmentally friendly technology: electrostatic spraying process body, anticorrosive and durable, prolong service life.

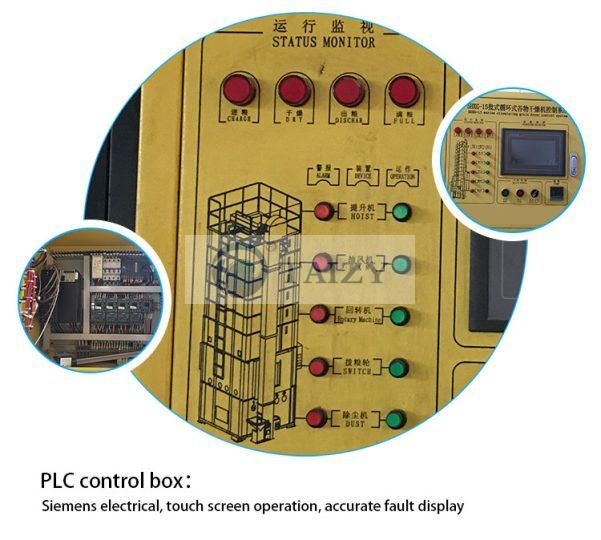

Proficient features of Taizy cereal drying machine

Compared with traditional drying equipment, the Taizy grain dryer is superior in terms of scope of application, energy efficiency, and drying effect, with the following characteristics:

- Wide range of applications: drying of maize, rice, rapeseed, millet and many other small and large grains.

- Low power operation: total power is only 7.6kW, no additional transformer required, easy to install.

- More uniform drying: the drying layer is up to 2.7 meters high, the grains are heated for a longer time and with better effect.

- Not easy to clog: optimized structure, smooth ventilation, avoiding the problem of clogging of the traditional sieve plate.

- Energy saving and consumption reduction: low drying cost, small grain crushing rate, and improve grain quality.

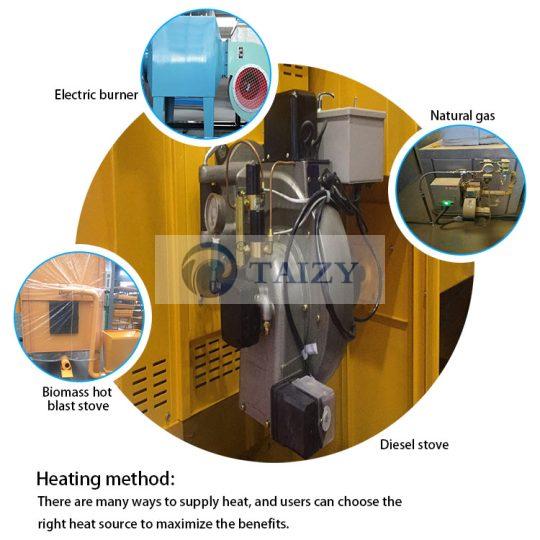

Main features of the fuel part

- Simple structure, lightweight and durable, easy to install.

- With double nozzle burner, good atomization, fast heating, and accurate temperature control.

- Double-layer combustion chamber design, using 310S high-temperature stainless steel, full combustion, energy saving, and environmental protection.

- No smoke emission, no pollution of grain, guarantee the quality.

- Intelligent and easy to operate, support biomass fuel, thermal efficiency up to 85%.

- With an automatic constant temperature ventilation device, stable temperature control reduces drying costs.

How to avoid broken corn during operation?

In order to ensure that the dried corn is intact and not broken, Taizy grain drying machine adopts several optimized designs, effectively avoiding the secondary damage caused by traditional equipment.

- Eliminate screw conveyor: self-flowing design to avoid high-speed collision between corn and equipment.

- Raise the height of the equipment: corn falls naturally, reducing the extrusion and impact.

- Reduce the secondary damage: avoid the collision of the corn which has been damaged after threshing again.

- Drying more evenly: optimize the hot air circulation, reduce the crushing rate, and improve the quality of finished products.

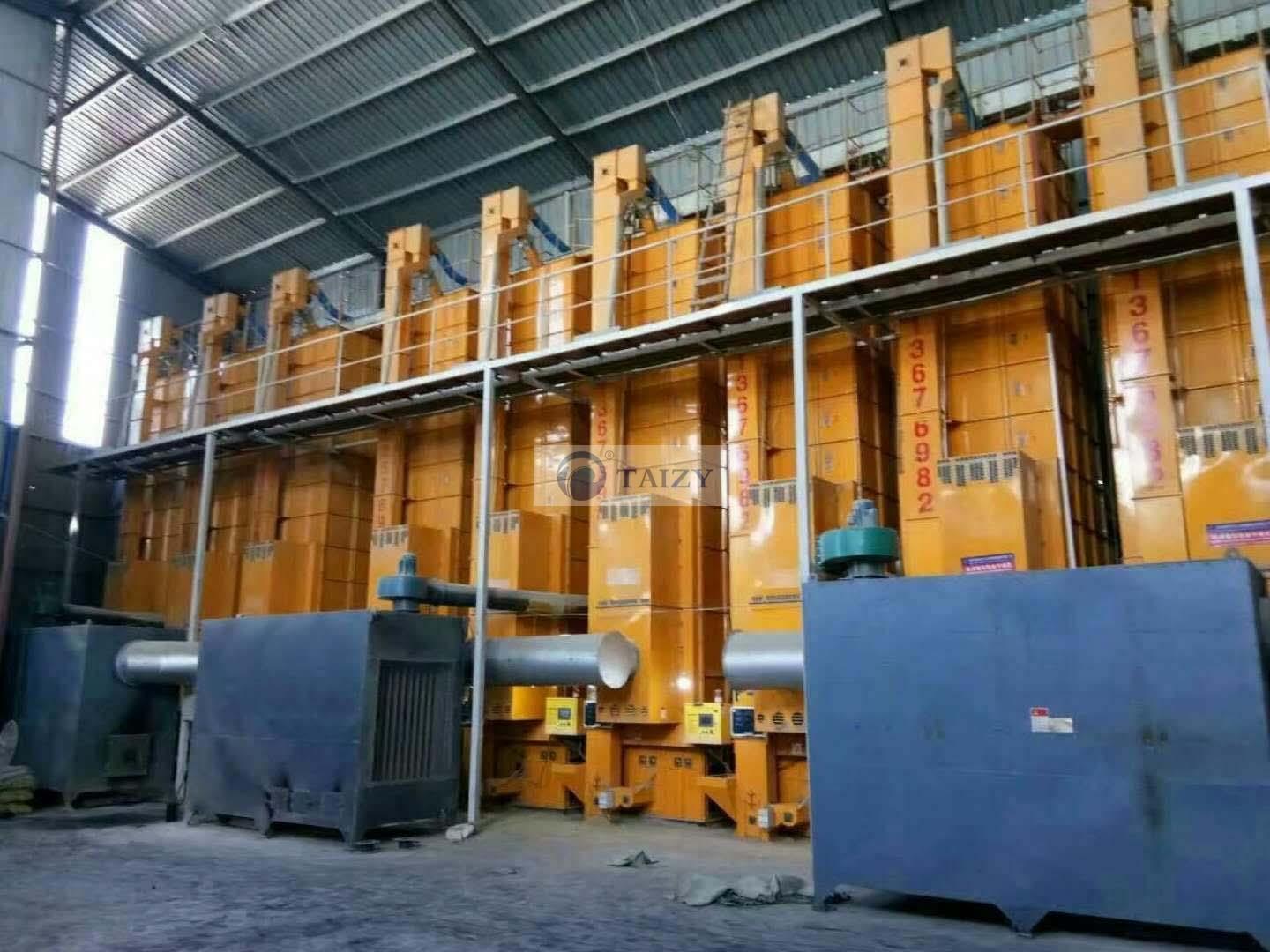

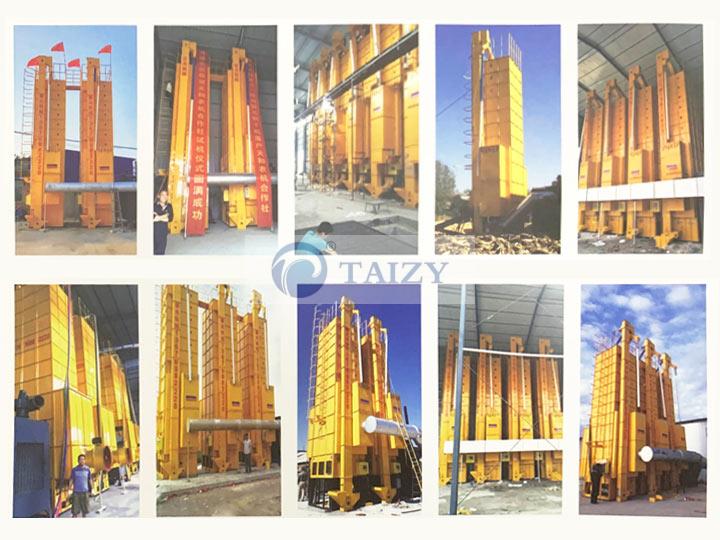

Successful cases of grain drying equipment

Grain dryers are popular all over the world, especially in developed agricultural and grain-producing countries.

Our grain dryers have been successfully exported to many countries, including the United States, Brazil, India, Russia, Nigeria, Ukraine, Thailand, Vietnam, Philippines, Pakistan, Ethiopia, and Kenya.

Structure of wheat dryer

The main components that make the machine work are shown below.

Nowadays, the yield of the grains is high. People need to process the grain by using all kinds of machines. You can use the corn harvester to reap the corn effectively. And then use the corn thresher to get corn kernels. Also, to avoid the mildew of grain, a grain dryer is needed.

We are ready to provide you with detailed product information and professional consulting services as you consider your choice of grain dryer. Feel free to contact us at any time, we look forward to answering your questions and ensuring that you select the best drying solution for your needs.