Recently, our factory completed the production of 16 sets of forage baler wrapper machines, which have now been successfully shipped to Algeria. The customer in this partnership is a major farm operator in Algeria, dedicated to enhancing the packaging efficiency and logistics management of agricultural products. This company not only has extensive crop planting operations but is also involved in the deep processing and export of agricultural goods.

Customer background and demand analysis

The customer demonstrated a strong grasp of the industry when selecting forage baler wrapper machines for their procurement. Before making a purchase, they engaged in market research and sought technical consultations to thoroughly assess the performance, efficiency, and market feedback of comparable products. This indicates that customers apply strict criteria in their equipment selection and are capable of pinpointing the optimal solution to fulfill their requirements.

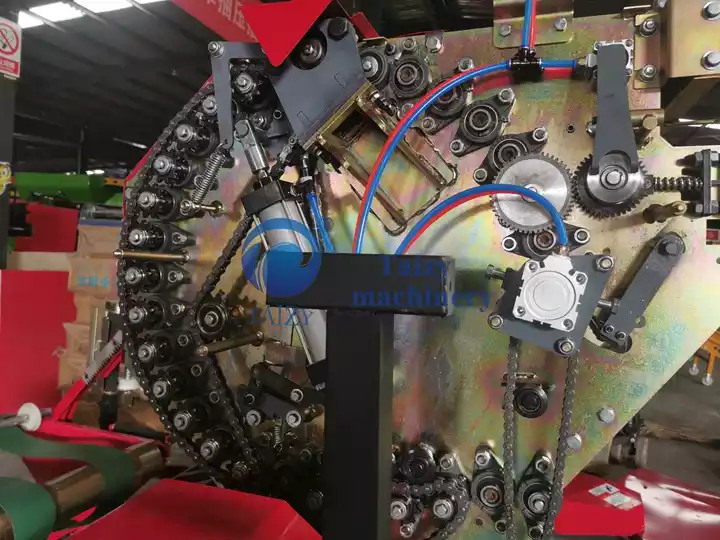

The customer-focused closely on the machine’s internal structure design, demonstrating a thorough consideration of its durability, ease of maintenance, and long-term operating costs. They hope that the equipment they purchase will align well with their production process and deliver efficient, stable performance to meet their increasing packaging demands.

Comprehensive transformation and upgrade of forage baler wrapper

The forage baler wrapper machine delivered by our company this time is designed to improve the efficiency of agricultural product packaging, effectively protect agricultural products, and reduce losses during transportation. This baling and wrapping machine has undergone comprehensive transformation and upgrades, including:

- Tire upgrade: upgraded to larger and wider solid tires that are robust and durable, making them less prone to breakage.

- Bearing upgrade: switched from the original 203 bearing to a 204 bearing to lower the failure rate.

- Increased number of screws: improved structural stability and prolonged the lifespan of the equipment.

- Thickened net roller shaft: enhanced net smoothness and boosted operating efficiency.

These improvements further enhance the durability and operational stability of the equipment, making it more adaptable to the production needs of customers. If you are interested in the machine, you can click Full-Automatic Silage Baler Machine Forage Baling Equipment to view more details. Feel free to contact us directly by leaving a message in the form on the right.