High-Efficiency Maize Corn Cleaner Grain Cleaning Equipment For Sale

High-Efficiency Maize Corn Cleaner Grain Cleaning Equipment For Sale

Grain cleaner | Grain screener

The corn cleaner machine is mainly used to clean wheat, corn, soybean, and other grain crops with large, medium, and small impurities. It is an important piece of equipment indispensable to clean the original grain before wheat flour processing. The output can reach 500-600kg/h.

This grain cleaning machine has four parts: automatic loading, two-layer screening, net grain de-stoning, wheat beating, and de-mixing. It has the advantages of small volume, lightweight, low power consumption, stable performance, advanced process, and multi-functional integration. The corn cleaner is the ideal supporting equipment for corn grits making machine and corn flour milling machinery.

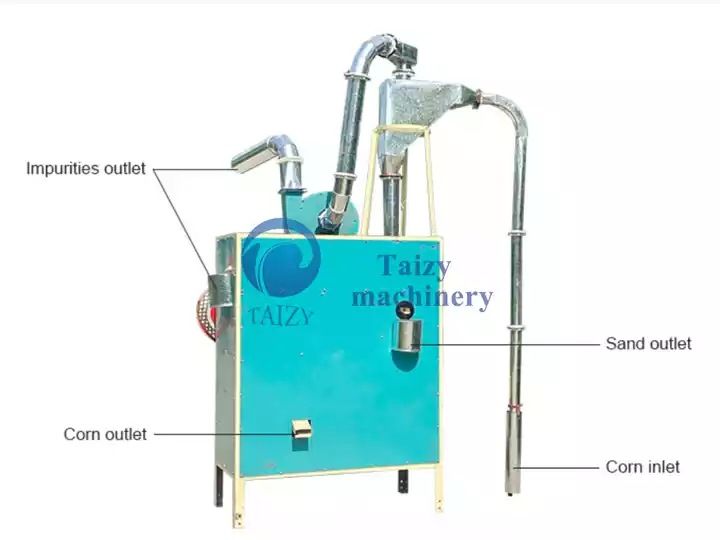

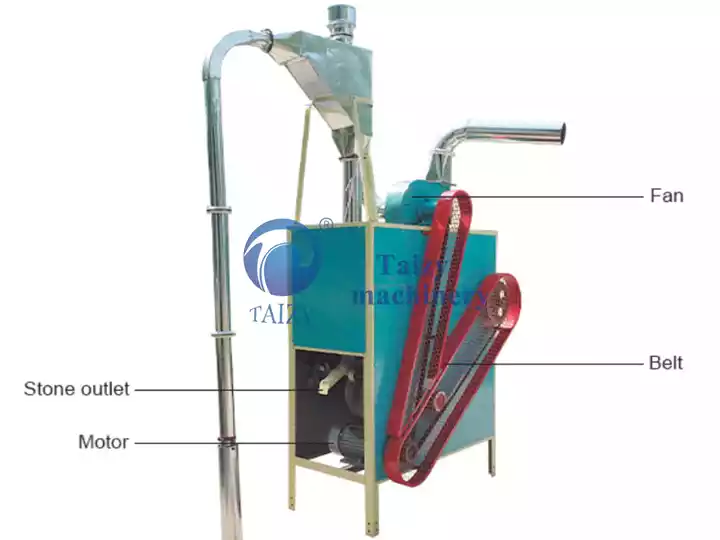

Corn cleaner structure and function

- Fan: automatic loading and dust suction, the processed material is carried and lifted by high-speed airflow and enters into the triangle box unloader through the conveying pipe. Due to gravity, the material sinks and flows out through the closed air pipe, and enters into the first flat screen.

- Flat sieve: the use of materials and impurities of different particle sizes, remove the size than the material is small or large impurities. The sieve adopts the upper and lower double sieve structure, large amplitude, and high rate of impurity removal.

- De-stone machine: the use of materials with a different specific gravity of stone, suspension speed is different. The action of the fan on the blowing wind, due to the vibration of the sieve plate, removes the material from the large impurities.

- Wheat beater: the use of high-speed rotation of the beating plate to combat materials and impurities. The soil and friable impurities attached to the material will be broken and discharged through the discharge port.

Maize cleaning machine technical parameters

- External dimensions: 1200*770*2900mm(length×width×height)

- Weight: 300kg

- Output: 600kg/h

- Supporting power: 4 level 3kw

- Blower speed: 3100rpm

- Wheat beater speed: 1200rpm

- Sieve body vibration frequency: 550rpm

- De-stoning machine fan speed: 1230rpm

Precautions for grain cleaner installation

- The installation foundation must be level and the anchor bolts must be tight.

- The rotation direction of the motor should be consistent with the rotation direction marked on the spindle.

- The installation of wires and motors should be completed by electricians and technicians together.

- This corn cleaner machine is used in conjunction with other milling equipment, taking into account the relative position of the grain bin.

Installation adjustment and operation

Before installation, check whether there is any debris on the equipment. The operator should first ensure the safety of people and machines.

- After the corn cleaner machine is idling for 1-2 minutes, open the feeder under normal conditions, and adjust the gate to the appropriate position from small to large.

- The pressure of the elastic band of the closed air duct should be adjusted so that the corn is evenly discharged, and the corn is not out of the fan outlet. It should not be too loose or too tight.

- De-stoning machine under the mouth and wheat beater inlet clearance should be properly coordinated. Otherwise, any impact will affect the effect of de-stoning.

- Tight cooperation between the outlet of the wheat beater and the inlet of the mixer. There shall be no running material leakage phenomenon.

- Ensure wheat moisture, durum wheat moisture can be 15.5%-16.5%.

- The air outlet of the fan should not be bundled with bags to ensure that the air outlet is unobstructed.

From corn sowing to harvesting to grit milling and a series of other processes, we have the corresponding machines. Please feel free to contact us, tell us your needs, and we will recommend the most suitable machine for you.