Brick making machine for sale | block making machine

Brick making machine for sale | block making machine

Brick Molding Machine/Brick Press Machine

Features at a Glance

What is the brick making machine?

As its name implies, the brick machine is the mechanical equipment for the production of bricks. It generally uses stone powder, fly ash, slag, gravel, sand, water, etc. as raw materials to produce new wall materials, such as autoclaved fly ash bricks, autoclaved ash sand bricks, and aerated concrete products.

A summary is as follows: the scientific ratio of raw materials—-add water and stir—- high-pressure vibration molding—-short time drying—–the finished brick

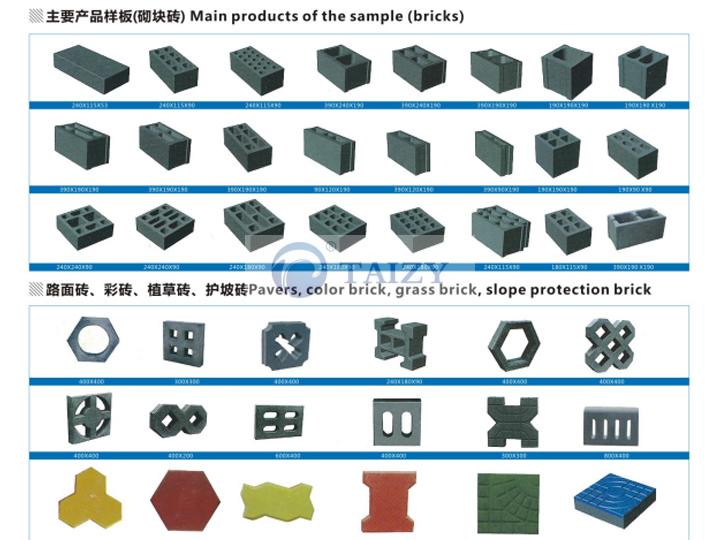

Types of bricks made by block making machine

cement brick

composition of cement bricks

Cement brick is a broad term, including cement standard bricks, cement hollow bricks, cement porous bricks, cement block bricks, and cement color, etc. However, the production process and flow of these bricks are the same. Of course, there are differences. There are many raw materials for the production of cement bricks. Most of the raw materials used by cement brick factories are stones, sand, fly ash, slag, slag, construction waste, ceramics, etc. By the way, there is cement, and cement is the important ingredient of cement bricks. Because the molding of cement bricks mainly relies on cement as an adhesive.

Clay brick

Composition of clay bricks

Clay bricks are made of clay as the main raw material, which is stirred into plasticity and formed by mechanical extrusion. The extruded soil blocks are called green bricks, which are sent into the kiln after air-drying, where they are calcined at a high temperature of 900-1000°C to become bricks. It is divided into ordinary clay bricks, multi-clinker clay bricks, raw material clay bricks, and high-silica clay bricks. It has the characteristics of good high-temperature performance and good heat and shock resistance.

The power of brick making machine

Our brick molding machine is available in electric and diesel engine models. You can choose the power mode of the brick-making machine according to your electricity. The automatic brick making machine is equipped with a 7.5w motor. The maximum power of our manual brick making machine is up to 7w, and it can also be equipped with an 8-horsepower diesel engine.

Kinds of our block making machine

We have automatic block making machines and manual block making machines. Among them, the manual block making machine has many models for you to choose from. Both types of brick machines can produce cement bricks and clay bricks.

What is the process of making bricks?

All raw materials-mixing-forming-drying (kiln firing)-finished product

Select raw materials

Maybe you have all the raw materials mentioned above. At this time, it will be more abundant and cheaper. Choosing rich materials and cheap prices will save you a large part of the cost.

Mixing the materials

After selecting the raw materials, add a certain amount of cement and water, and then mix the materials. Long mixing time can mix evenly. The strength of dry mixing in 20 minutes is 15-23% higher than that in 10 minutes. the time of wet mixing is good when the material does not agglomerate. The storage time of the mixed material is about 2 hours. If the time is too long or too short, the compressive strength of the brick will be reduced.

Molding

The pressure when the clay cement brick is molded is preferably 500 kg per square centimeter. Under this pressure, its products have high compressive strength and good water resistance. The pressure is too low to be easily compacted.

curing conditions

Clay cement bricks are generally protected by solar energy. The intensity of natural curing for 7 days is equivalent to 67 to 90% of the intensity of 28 days. Therefore, if the curing site is small, the clay cement bricks can leave the factory after 7 days of natural curing.

What are the types of bricks?

The current types of bricks include lightweight aggregate concrete small hollow blocks, sintered ordinary bricks, sintered porous bricks, autoclaved sand-lime bricks, fly ash bricks, small concrete hollow blocks, hollow bricks, and autoclaved aerated concrete blocks. All the above types of bricks can be made by our brick making machine.

Matching equipment with brick making machine

Small mixer

Buy our brick making machine, you can also equip a small mixer. Because bricks always require a lot of raw materials to be mixed. The mixing effect of the machine is more uniform than manual mixing so that the bricks you make will be uniform in color, and high in quality. It will be sold at a good price.

What is the brick making machine price?

As mentioned above, we have many types of brick machines. The most popular one is the manual block making machine. It is simple in operation and has high efficiency, it can produce 8000-10000 bricks in one hour. You can contact us if you need the brick making machine. We will introduce a precise brick machine for you.

Technical Parameters

| Model | DF2-45 | DF3-45 | DF-diesel | DF4-35A |

| Equipped with power | 1.1kw | 1.1kw | 8P | 4.8kw |

| Molding time | 45s | 45s | 45s | 35s |

| Brick making speed | 3600pcs 240*53*110mm(Standard Brick) | 8000pcs 240*53*115mm(Standard Brick) | 3600pcs 240*53*110mm(Standard Brick) | 15000pcs 240*53*110mm(Standard Brick) |

| 600pcs 390*190*190mm (Hollow Brick) | 1000pcs 390*190*190mm(Hollow Brick) | 600pcs 390*190*190mm (Hollow Brick) | 2400pcs 390*190*190mm (Hollow Brick) | |

| Machine size | 900*700*1100mm | 1100*1050*1300mm | 1900*1000*1550mm | 1250*1350*15500mm |

| Machine weight | 200kg | 300kg | 250kg | 750kg |

| Number of operators | 1-2 | 1-2 | 1-2 | 1-2 |

If you are interested in our machines, welcome to contact us at any time, we provide you with more detailed information and quotation, looking forward to cooperating with you.