Silage Baling and Wrapping Machine Hay Baler Equipment

Silage Baling and Wrapping Machine Hay Baler Equipment

Silage feed baler | Hay baler wrapper machine

Features at a Glance

The silage baling machine and wrapping machine is a kind of agricultural and animal husbandry equipment, which is widely used in the collection and preservation of forage, straw, and other feeds.

The equipment bundles and wraps the feed through plastic film, net rope or twine, and realizes silage fermentation in an anaerobic environment. This effectively locks the feed nutrients, extends the preservation time and meets the year-round feeding needs of ruminant livestock such as cattle, sheep, horses, deer and donkeys.

Especially the TZ-55-52 baling and wrapping machine has a compact structure, stable performance and easy operation. It is equipped with a 5.5kw motor, with dimensions of 1600x1450x1060mm, and can bale 30-50 bales of grass per hour, with each bale weighing 30-90kg.

The number of layers of mulching is 2-4, and the weight after mulching is 135kg, which is the ideal choice for small and medium scale farmers and farms to improve the efficiency of feed processing.

Silage baler machine application scope

- Widely applicable raw materials: it can be used for silage pasture, fresh straw and dry straw, such as wheat straw, rice straw, soybean straw, corn stalks, etc.

- Suitable for many kinds of livestock feeding: baled silage can be fed to cattle, sheep, horses, deer, donkeys, pigs, camels, rabbits and other kinds of livestock and ruminants.

- Adaptable to different regions and farming scales: it can be used efficiently in family farms, cooperatives, and small and medium-sized farms, and is convenient for long-term storage and transportation.

Customized large tire traction baler wrapper

Our latest customized mobile 55-52 silage baler and wrapper has been enhanced from the original model, now featuring larger tires that facilitate easy towing and quick movement across various plots of land, significantly boosting operational flexibility.

This upgrade is particularly beneficial for Africa and other areas with challenging terrain and dispersed farms, making the process of silage baling and storage more efficient and user-friendly. Whether for a large ranch or a small farm, this model stands out as an excellent option to enhance agricultural productivity.

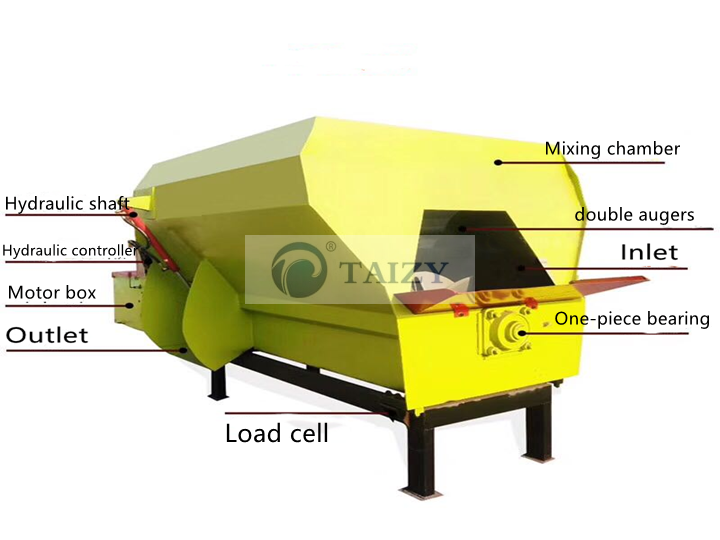

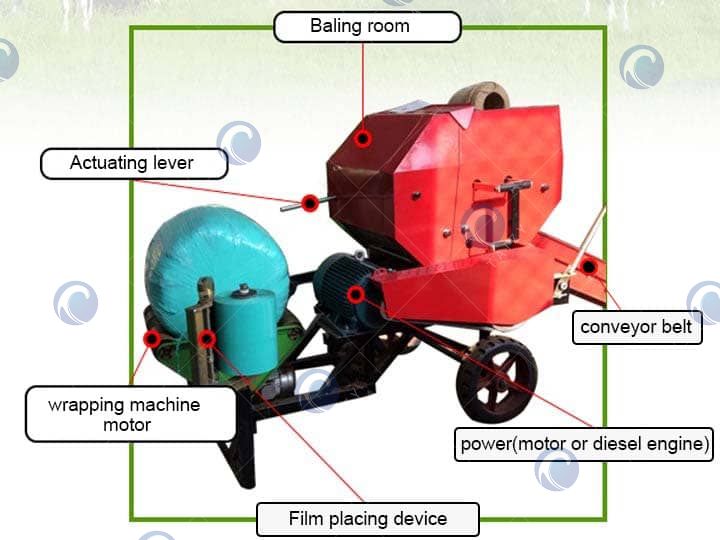

Hay baler machine main structure

- Smashing part

Silage or forage is prepared by shredding, crushing, and extruding to break down the tough stem segments on the straw’s surface, making it easier for livestock to consume the parts of the straw that are not directly edible. - Baling part

The forage is quickly and evenly fed into the bale working chamber for compression. Once each bale weighs approximately 80kg, the signal wheel rotates at a steady speed, engaging the winding clutch handle to wrap the bale with rope. After cutting the rope, the user operates the opening handle to release the bale. - Wrapping part

The bales are positioned on the two parallel belts of the wrapping machine. When the wrapping switch is activated, it rotates the frame to move the bales. The bales then stretch the plastic film to wrap themselves automatically. Users can also adjust the number of coating layers, choosing between 2 to 4 layers.

Working principle of baler machine

- The operator uses the shovel to put the straw into the inlet.

- After several minutes, the bundles will be finished under the force of ropes.

- The user pushes the bundles forward and then presses a button, and bundles will be baled automatically.

How to install a corn silage baler machine?

The red chip of the silage film is facing up and then fixed on the film conveying frame. Then you should use a fixture to adjust its angle. The distance between silage films should be proper. If the distance is too wide, it can be adjusted by two screws under the conveyor.

Second, place the rope to pass through the hole in the baling machine and wrapping machine.

Third, connect the wires. You should connect the three-phase electric wires to the inside of the control box. There are two-time adjusters including conveying rope and baling, which can be adjusted.

Fourth, the installation of the air pump. Connect the air pump motor to the power supply. Connect the air pipe to the machine, and open the vent switch. The air pressure during the operation should be maintained between 0.6 and 0.8Pa.

Check all parts of the baling machine and wrapping machine carefully before use and confirm that the machine is running in the right direction.

Parameters of baling machine and wrapping machine

| Model | TZ-55-52 |

| Motor | 5.5KW |

| Dimension | 1600x1450x1060mm |

| Weight | 380kg |

| Operating speed | 30-50bundles/h |

| Bale weight | 30-90kg |

| Coated layer | 2-4 layer |

| Coated efficiency | 12seconds/bale 2 layers… |

| Weight of Coated machine | 135kg |

| Baling type | Round shape with film for long time storage |

| Raw material | Suitable for nearly all kinds of silage, straws of wheat, rice, soybean, corn, etc fresh or dry |

Silage packing baler machine sold to Bangladesh

Our clients are primarily from Bangladesh, and they reach out to us through our YouTube channel. The customer intends to purchase a baling machine and wrapping machine for personal use.

During discussions, our sales managers gather information about the client’s budget. As a result, the sales manager suggested the small silage packing baler machine TZ-55-52.

Customers believe this machine fits their requirements well. Additionally, the client expressed a desire to pack the forage using nets and ropes. This machine is versatile enough to accommodate both options, catering to the customer’s needs.

Normally, before using the baling machine and wrapping machine, we can crush the forage with a chaff cutter. This is because the treated forage is easier to bale.

If you want to know more details about our silage baling machine and wrapping machines, please click Silage Baler Machine | Full-Automatic Silage Baling Machine. Feel free to contact us at any time.

FAQ

What is the power of the machine?

The power can be a diesel engine, gasoline engine, or electric motor. Different models of machines have different power requirements.

What is the purpose of the baler wrapping machine?

Dry or wet silage, weeds, straw.

How long can the packaged feed be stored?

2-3 years.

Does the machine use an air compressor?

Fully automatic needs, semi-automatic does not need an air compressor.