Automatic Square Straw Picking And Strapping Machine

Automatic Square Straw Picking And Strapping Machine

Hay harvester and baler | Straw picking and baling machine

Features at a Glance

The automatic square straw picking and strapping machine can work with a tractor to complete the picking and bundling of forage, soybean, rice straw, wheat, corn, and other crop stalks.

The resulting bales are small, compact, loose inside, and tight outside. Also, the bale has good air permeability, which makes it easy to transport and store. The machine has a baling rate of over 99%.

The popularization of this machine has played a huge role in solving straw recycling. It also improves the environmental conditions caused by rural straw burning. This improves the quality of straw use.

It is ideal equipment for forage collection and bundling. Since the launch of this machine, it has been the favorite machine of farmers. And is a good helper to make a fortune.

For baling and preserving wet forage, you can use our silage baler.

Bale details of straw picker baler recycling machine

This automatic square straw picking and strapping machine uses two bundles of plastic rope to make a total of about 1,000 bales, finishing at 15-20 per hour.

The maximum harvesting width of the machine is 2 meters, the bale size is 114*40*30cm, and the weight of each bale is 25-35kg. It can be equipped with a simple bale wrapping machine as follows.

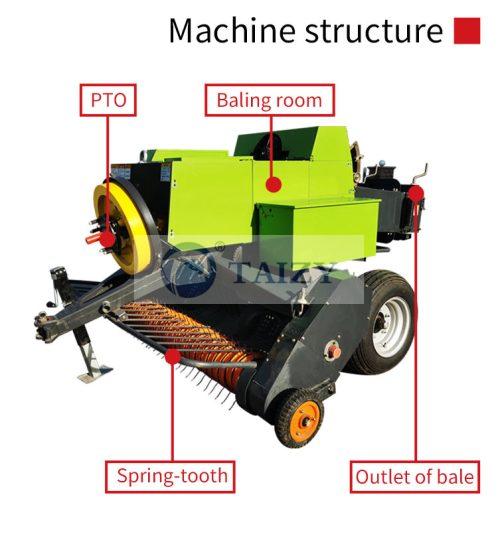

Automatic square straw picking and strapping machine structure

The components of the straw picking and baling machine: A traction beam, a picker, a screw conveyor, a feeding mechanism, a piston, a baling chamber, a baling mechanism, a bale density adjustment device, and a transmission system.

- The function of the picker is to pick up the grass strips laid on the ground. And then raise the feeding platform. The picker adopts a four-row spring-toothed roller structure.

- The function of the conveying and feeding mechanism is to collect the materials laterally. And then feed them into the baling chamber. It also includes a screw auger conveyor and a feeding fork mechanism.

- The function of the piston and the baling chamber is to compress the material. And then fed into the baling chamber. The piston is a crank connecting rod mechanism. The binding chamber is a rectangular cavity formed by welding steel plates.

- The function of the bale density controller is to adjust the bale density. According to forage species and humidity, the operator can adjust the spring tension to obtain a moderately tight bale.

Working principle of straw picking and baling machine

Automatic square straw picking and strapping machine work through the tractor’s powder. In the process of field operations, the spring teeth of the picker pick up the ground grass strips.

The symmetrical screw conveyor pushes the material from both sides of the platform to the feeding inlet.

The feeding fork will add the accumulated straws at the feeding inlet into the baling chamber during its working process. Under the upward action of the piston, the straw is gradually compacted.

When the length of the bale reaches the set length. The strapping mechanism clutch starts the strapping operation. In the working process of the knotter, the two bundles of rope envelop the bale.

Then the subsequent materials will push the bundled bales gradually to the exit of the baling chamber. And then fall to the ground through the baling plate.

Square straw picker and baler machine parameters

| Model | Picker with | Picker structure type | Knotter type | Number of knotters | Reciprocation times of the bundled piston | Dimensions | Supporting power |

| 9YFQ-2.2 | 2240mm | Spring tooth | D | 2 | 100/min | 4150*2850*1800mm | ≥36.7kw |

Main features of straw baling harvester machine

- Knotting device imported from Germany (Rasboa, Germany producing). The automatic square straw picking and strapping machine has high bundling density, and the bundling rate is as high as 99%.

- The whole machine adopts the symmetrical structure design of the longitudinal axis: mid-mounted traction, good driving stability, and a small turning radius.

- Using a hollow auger structure to make the crop feed more smoothly. No accumulation, no entanglement.

- A double-side brake bundling damping device makes the bundling action more stable. The double-row chain makes the machine more suitable for heavy-duty bundling operations. Wide-section tires make the walking operation more stable.

- It can greatly reduce the storage area, improve the transportation capacity, and reduce the possibility of fire.

- Easy to store. The bundled grass volume is smaller two-thirds than of unbaled grass, which can greatly reduce the area of the pasture.

- Convenient for loading, unloading, and transportation. The machine can make full use of the carrying capacity of the means of transport. Generally, the transportation capacity can increase by 2-3 times. It can also save labor and transportation costs by more than 50%.

Contact us at any time

Thank you for reading this article about our automatic square straw picking and strapping machine. If you have any questions or need detailed information about this machine, please feel free to contact our professional team. You can send us your specific needs through the message form on the right. We hope to provide you with the right equipment for your straw recycling program.