To improve efficiency and durability, our factory has rolled out several innovative upgrades to our silage baling and wrapping machines. These enhancements are designed to boost productivity while reducing downtime and maintenance needs. Here are the key upgrades that have been implemented:

Enhanced mobility and durability

- Larger solid tires: the small rubber tires have been upgraded to larger solid tires. These new tires can be easily moved with a forklift, improving both mobility and durability. Their solid design removes the risk of tire rupture, leading to smoother operation.

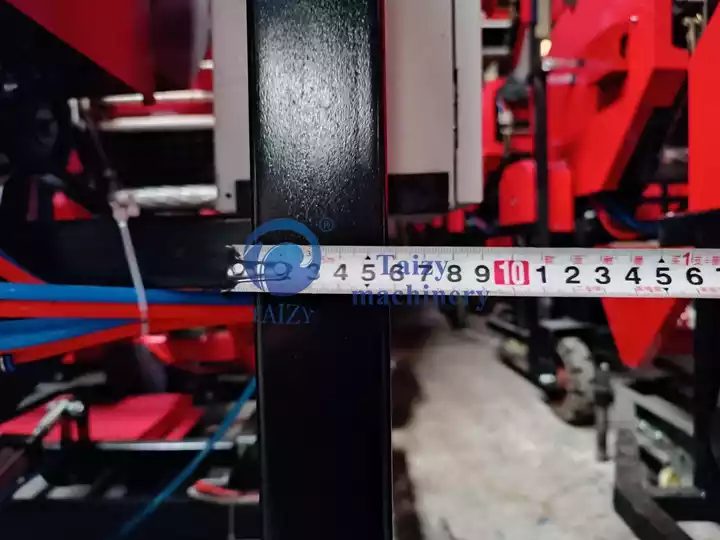

- Reinforced framework: the frame has been enhanced from 4x4cm to 5x5cm, and the entire machine now incorporates thicker materials. This reinforcement boosts stability and prolongs the silage baling and wrapping machine’s lifespan.

Upgraded bearings and corrosion resistance

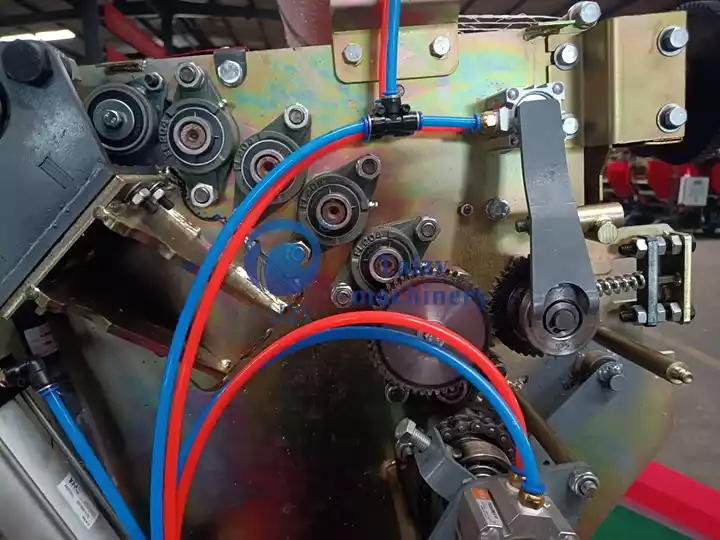

- Bearing enhancements: the previous 203 bearings have been upgraded to 204 bearings, featuring a thicker shaft in between. These larger, sturdier bearings provide smoother machine operation and greatly decrease the likelihood of failure.

- Corrosion-resistant materials: by using acid-washed cold steel plates, the silage baling and wrapping machine is now protected against water corrosion and rust. This improvement boosts overall durability and minimizes maintenance needs over time.

Advanced conveyor system and net binding

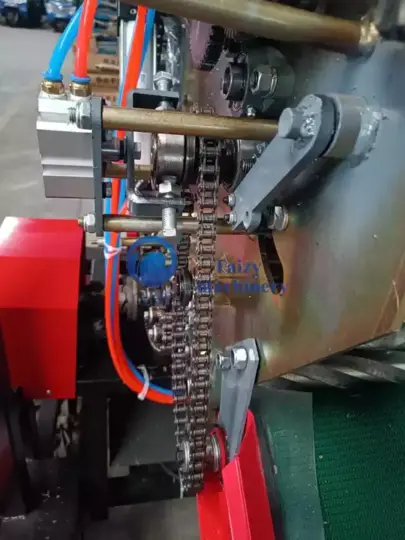

- Chain-controlled conveyor belt: the conveyor belt is now managed by a dedicated chain, featuring a cylinder separator. This setup ensures that the machine automatically halts material feeding when the packing chamber reaches capacity, as indicated by a load alert light.

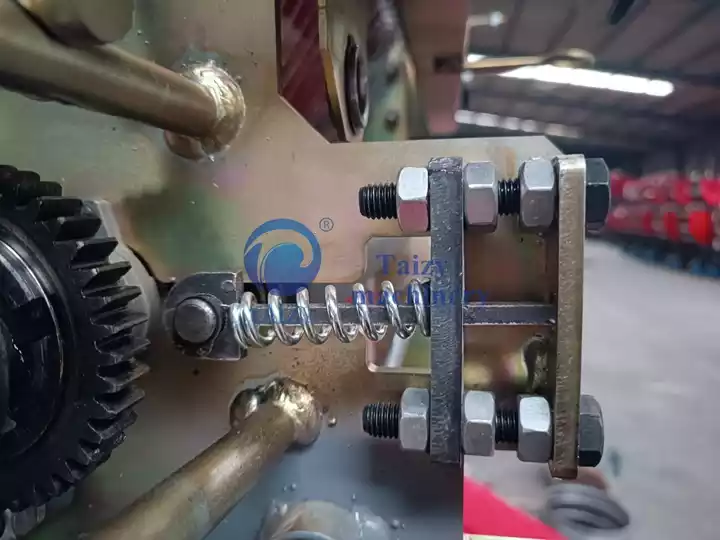

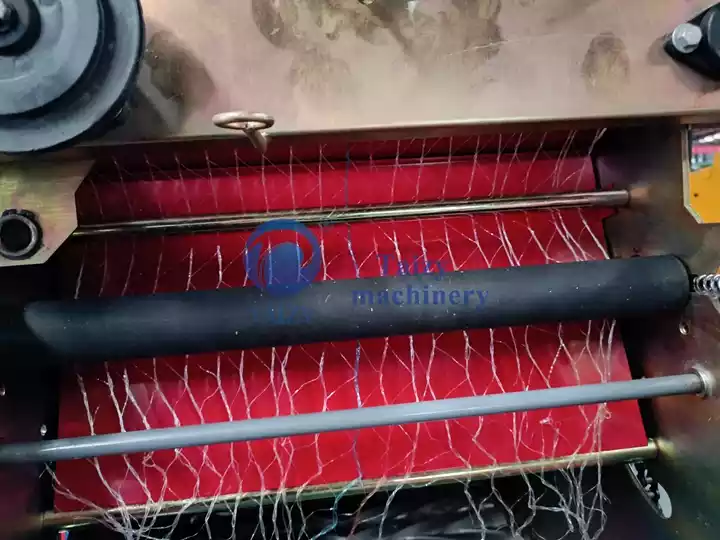

- Improved net binding: the baling rollers have been reinforced, and the net frame has been elevated. A separate clutch now manages the net binding, enhancing the process and reducing the risk of clogging.

- Adjustable roller tension: a spring has been incorporated to regulate the tension of the rollers. The transition from one screw to two screws allows for better control over the net binding, resulting in smoother and more stable operations.

Structural reinforcement

An additional frame has been incorporated beneath the film wrapping machine, greatly reinforcing the overall structure. This extra support further improves the machine’s stability and durability during heavy usage.

Our factory has been upgraded with these improvements to improve durability and operating procedures, enabling you to maximize productivity and minimize operational interruptions. We process different models of silage baling and wrapping machines: Full-Automatic Silage Baler Machine Forage Baling Equipment, please feel free to contact us if you have any needs.