At the beginning of this month, our factory completed the processing and production of a complete set of 15 tons/day capacity combined rice mill plant, and recently successfully shipped them to Cuba. The customer is a company that is very concerned about the output of the rice milling unit. They clearly stated that they need to ensure efficient rice processing capabilities and good white rice quality.

Combined rice mill plant output and quality assurance

Our rice milling unit is designed to have a daily output of 15 tons of white rice. Under normal circumstances, 1000 kg of rice can be input, and about 700 kg of high-quality white rice can be produced. The customer is very satisfied with this output and proposed the need for a grain sorting machine to screen out bad rice.

In response to customer needs, we recommended an advanced color sorter. The color sorter can efficiently screen out bad rice to ensure that the final output is all high-quality white rice. We sent the customer a working video of the color sorter, showing its functions and effects in detail. The customer was very satisfied with our recommendation and immediately accepted the proposal.

Factory visit and detailed introduction

During further communication, the customer from Cuba expressed his desire to visit our factory in person. We warmly received the customer and introduced the production process and technical parameters of the combined rice mill plant in detail. The customer highly appreciated our production equipment and factory management, which further enhanced their trust and willingness to cooperate.

The following are the confirmed machines detailed information:

| No. | Item | Model | Power(kw) | Total Power | Size | Weight |

| 1 | Elevator | TDTG18/07 | 0.75 | 23.3kw | Overall size: 3000*3000*3000mm | 1400kg |

| 2 | Paddy Rice Destoner | ZQS50 | 0.75+0.75 | |||

| 3 | Elevator | TDTG18/07*2 | 0.75 | |||

| 4 | Paddy Rice Husker(6InchRubber Roller) | LG15 | 4 | |||

| 5 | Gravity Paddy Separator | MGCZ70*5 | 0.75 | |||

| 6 | Rice Mill( Emery Roller) | NS150 | 15 | |||

| 7 | Rice Grader | 40 | 0.55 |

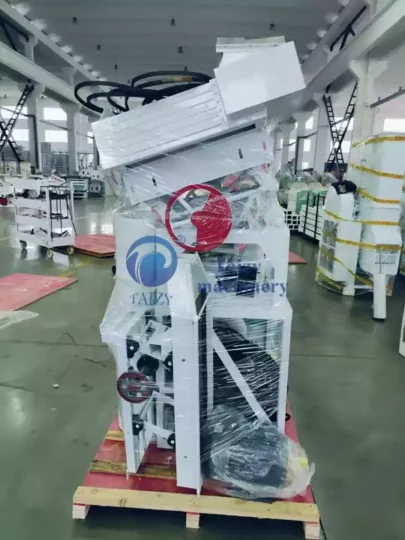

Packaging and delivery

After the machine is completed, we carefully pack each machine into a wooden box and mark it on the outside so that the customer can know the specific contents of each box. Such thoughtful detail processing allows customers to feel our professional and efficient service.

For more information about this machine, please click 15TPD Complete Rice Mill Plant Raw Grain Processing Equipment. Of course, our factory produces a variety of rice processing equipment with different capacities and combinations, which can be configured according to your needs and budget. You are welcome to consult our products at any time and welcome to visit our factory. We will provide a full range of services and look forward to more cooperation with you.