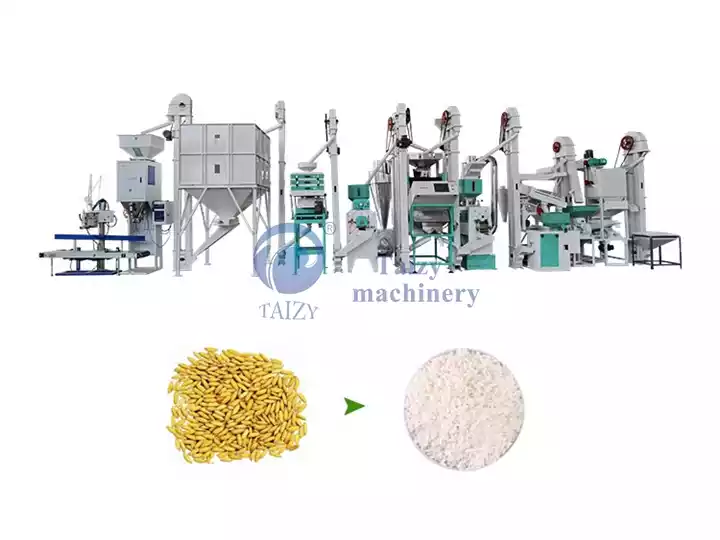

50-60Tons Per Day Complete Set Rice Processing Unit

This rice processing unit production line is uniquely designed to handle 50-60 tons of paddy per day, ensuring high yield and quality of rice, and is suitable for large-scale rice mills or grain processing enterprises.

This production line can be customized with different configurations according to user needs. It not only improves rice production efficiency but also realizes considerable cost savings, providing rice producers with a reliable, efficient, and advanced production solution.

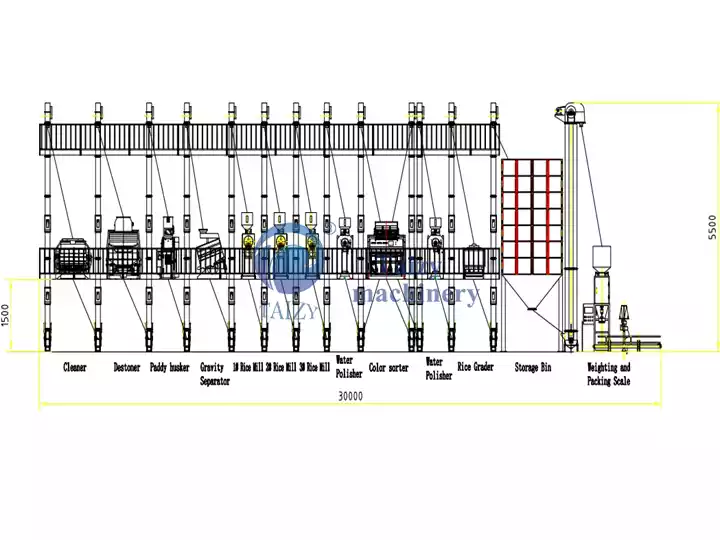

Main Structure of 60TPD Rice Processing Unit

The components of this line are shown below. It is important to note that in a production line with a capacity of 40 tons per day, 2 or 3 rice mills can be used, but in this case with a capacity of 50-60 tons, three mills must be used.

Purpose and Requirements of Rice Milling

Rice milling occupies an important position in the whole white rice making process, which is the most important process of rice processing, and also an important link to ensure the quality of rice, improve the rice yield, and reduce power consumption.

- The surface layer of brown rice contains a lot of crude fiber, which the human body is not easy to digest; in addition, brown rice does not easily absorb water and expand, not only increasing the cooking time, reducing the rate of rice, and the color is dark, viscosity is poor, bad taste. Therefore, brown rice must be removed from its skin through the rice processing unit.

- The degree of peeling of brown rice determines the precision of rice. The more skins removed from brown rice, the higher the precision of the finished rice, although the more serious the loss of nutrients. Various grades of rice, in addition to the different degrees of retention of the skin, there are other different indicators, such as the inclusion of impurities, broken, and so on.

In the brown rice processing unit, our machine can achieve the finished rice in line with the prescribed quality standards under the premise of maintaining the integrity of the rice grain, reducing broken rice, improving the strength of the rice, reducing costs, and ensuring production safety.

Combined Commercial Rice Mill Finished Product

- After the rice milling machine milled white rice, mixed with chaff and broken rice, and rice temperature is relatively high, which not only affects the quality of the finished product but is also not conducive to the storage of rice.

- Therefore, out-the-machine white rice in the finished product before packaging must be sorted out, so that the finished rice contains chaff, containing broken rate in line with the standard requirements, so that the temperature of the rice down to the range of storage, but also according to the national provisions of the finished product containing broken standards to grade.

- In addition, the people’s standard of living has been improved, and high taste and high-quality rice is gradually favored by consumers so that the rice can be surface treated so that it is crystal clear.

- Can also be contained in the rice grain color (mainly yellow rice, that is, the endosperm is yellow, and the normal color of the rice grain is different from the rice grain) to remove, to enhance its commercial value, and improve the quality of food.

After-sales and Installation Service

- We can design installation drawings according to your processing site, etc., and can ensure prompt and accurate on-site installation services after you purchase our rice processing units.

- In addition, we provide a full range of training to ensure that our customers understand how to properly operate and maintain the equipment.

- Our after-sales service team is always on standby to ensure that we can respond promptly to problems encountered in the operation of the equipment and provide remote support or on-site service.

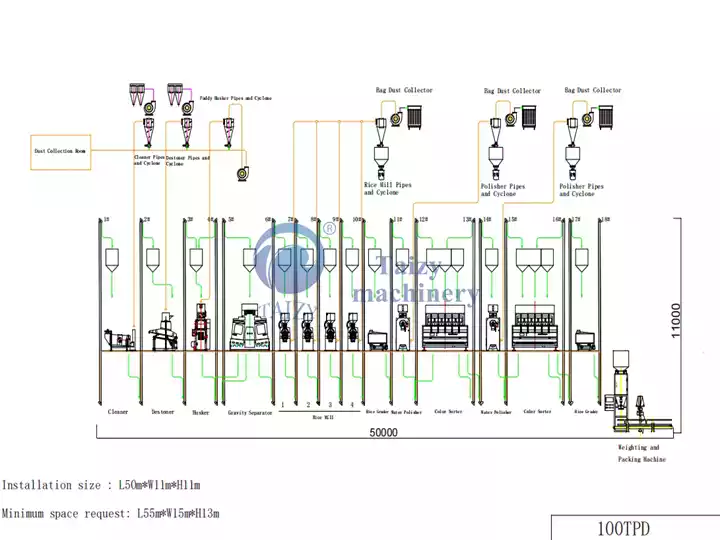

Finally, we can also design and produce a rice processing unit with a production capacity of 100 tons per day, as shown in the figure below for reference:

Welcome to browse this website to get more different configurations and outputs of rice processing, and, you can always contact us for more parameter information and quotations.