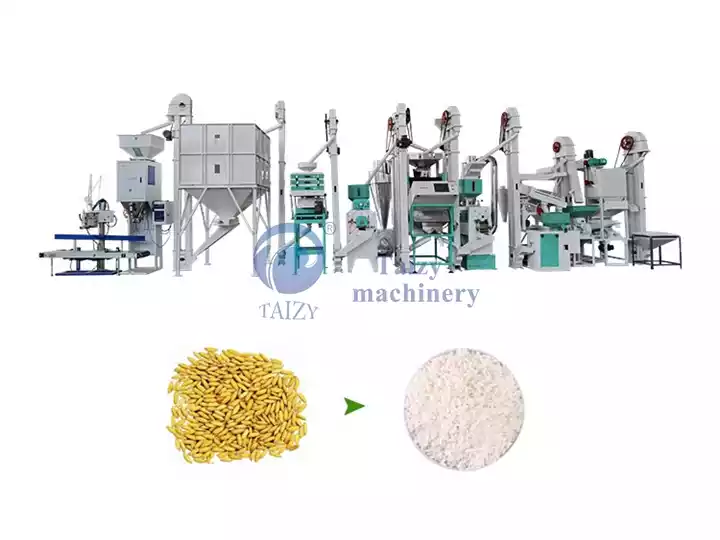

20Ton/Day Paddy Processing Unit For White Rice Making Plant

20Ton/Day Paddy Processing Unit For White Rice Making Plant

The paddy processing unit is a system of equipment specifically designed to process rice by removing the paddy from the husk and producing high-quality rice. This line typically includes processing such as de-husking, de-hulling, de-chaffing, and sieving, with each of these steps being performed by a range of specific machines and equipment working in tandem.

Rice milling lines can vary in size and capacity depending on demand, ranging from small-scale home use to large-scale industrial use.

20TPD Paddy Processing Unit Parameters

| No. | Item | Power(KW) | Power(KW) |

| 1 | Elevator | TDTG18/08 | 0.75 |

| 2 | Pre-cleaner | SCQY40 | 0.55 |

| 3 | Paddy Rice Destoner | ZQS50A | 1.1+1.5 |

| 4 | Elevator | TDTG18/08*2 | 0.75 |

| 5 | Paddy Rice Husker(6InchRubber Roller) | LG15A | 4 |

| 6 | Gravity Paddy Separator | MGCZ70*5A | 0.75 |

| 7 | Rice Mill(Emery Roller) | NS150 | 15 |

| 8 | Rice Grader | 40 | 0.55 |

Paddy Processing Unit Processable Raw Materials Show

The main raw material for a rice milling unit production line is paddy, usually the unprocessed grain of rice. Barley and wheat can also be processed.

The Finished Product You Can Get

Rice milling units usually produce rice that is white, with the outer bran (chaff) layer removed. This white rice is usually preferred because it has a better taste and appearance.

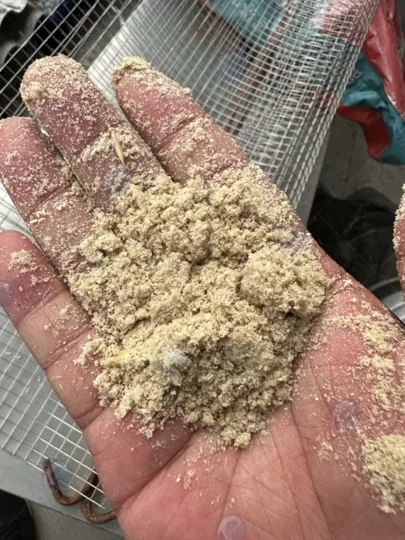

In addition to this, the husk obtained from the huller can be crushed and later made into animal feed.

Different rice milling unit production lines can produce different types of rice, such as long-grain aromatic rice, short-grain rice, brown rice, etc., to meet various market demands.

In addition, the rice husk obtained from the huller can be crushed and processed so that raw materials for making animal feed can be obtained. The following pictures show the mixture of husk before and after crushing.

20TPD Complete Paddy Processing Unit Working Process

In order to be processed from paddy to national standard rice for sale, it is necessary to go through the following standard process: raw material feeding → vibrating cleaner and de-stoning machine → huller → rice separator → rice milling machine → white rice grading sieve.

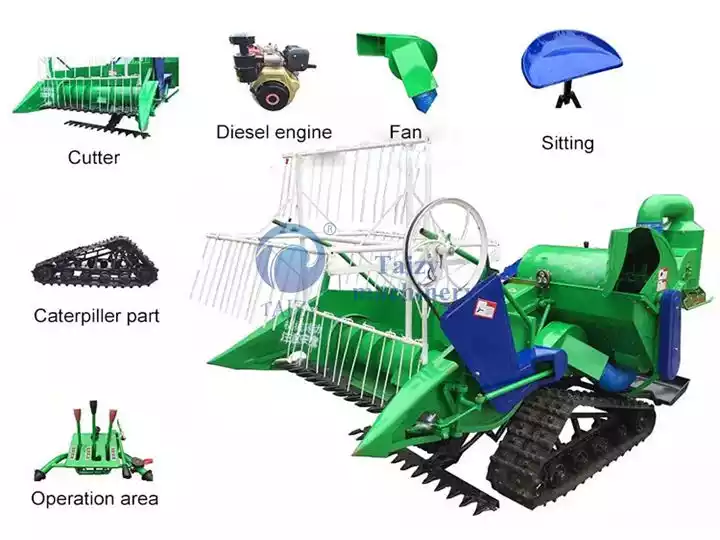

At the beginning of the paddy processing unit, the paddy is sent by single elevator to clean and de-stone to remove large impurities, and then sent by double elevator to huller for de-hulling, and the chaff is discharged by the fan or sucked into the crusher.

The chaff is discharged out of the machine by the fan or sucked into the crusher, and the mixture of grain and brown is conveyed to the gravity sieve for screening by the duplex elevator, and the unhulled rice is sent back to the huller by the gravity sieve.

The unhulled rice is sent back to the huller by the gravity sieve back to this conduit, and the brown rice enters into the rice milling machine, and the fine chaff is sucked off into the broken rice sieve after being polished by the rice milling machine.

What 20TPD Rice Mill Plant Consists of

- Pre-cleaner: Removing some of the impurities and unfilled grains from the rice grain;

- Destoning Machine: Separation of small stones from the rice grain;

- Dehuller: Removal of hulls from the paddy to obtain brown rice;

- Grain Separator: Separation of unhusked grain from brown rice;

- Rice Miller: Core equipment of the paddy processing unit, removing all or part of the bran layer and germ from brown rice;

- Sifting Device: Separating the small fragments from the milled rice.

Benefits Of Paddy Ric Mill Production Plant

Similar to the 15TPD paddy processing unit, except that a cleaner is added before the de-stoner.

- stable mechanical performance, convenient operation, and maintenance.

- the complete set of rice milling equipment covers a small area and has low investment.

- Improve the rice yield and reduce the broken rice.

- according to the needs of different customers, specially designed processes, flexible combinations, and processing into different high-quality rice.

- adopting steel structure form, each single unit is easy to dismantle and assemble, which is convenient for users to purchase the required single machine and other equipment.

Maintenance Of Major Machines

- The whole paddy processing unit maintenance should be carried out every 3 months, and overhaul should be carried out once a year.

- All transmission parts should be lubricated regularly.

- The bearing is generally changed to grease once in 6 months.

- The screen should be checked and cleaned every shift to prevent the screen holes from clogging, and the screen should be replaced in time after it is broken to prevent material leakage.

- Where the bearings are overheated, the grease is hardened, the grease color is darkened, or the grease surface has water droplets and dirt, the grease must be replaced immediately.

If you want to get more delicate white rice, we also have a high-quality version of the paddy processing unit production line available, you can contact us. We will customize a special rice milling plant design according to your detailed requirements.