Peanut groundnut shell removing machine

Peanut groundnut shell removing machine

Peanut Sheller/Groundnut Shelling Machine

Features at a Glance

The use of peanut shell removing machines is increasing year by year. This is because peanuts are one of the oil crops. And people can eat it after simple processing. The first step in processing peanuts is to remove the peanut shells.

Now the planting area of peanuts is large and the yield is high. Therefore, peeling peanuts manually will consume a lot of manpower and time. Using a peanut sheller can solve this problem. To help people save time and improve work efficiency. Peanuts processed by the groundnut have fewer impurities and less broken rate. And people can express oil by using the screw oil press machine.

Meanwhile, we also have other types of peanut shelling machine available, click for details: Peanut sheller removing machine | removing groundnut shell, Peanut sheller removing machine | removing groundnut shell, and Peanut Sheller shelling machine / groundnut sheller factory.

Introduction of the peanut shell removing machine

A peanut shell removing machine is the equipment that can clean peanut shells. We have complete machine models. And different models have different capacities. This passage is about the TBH-200 peanut shelling machine, which can process 200kg of groundnuts per hour.

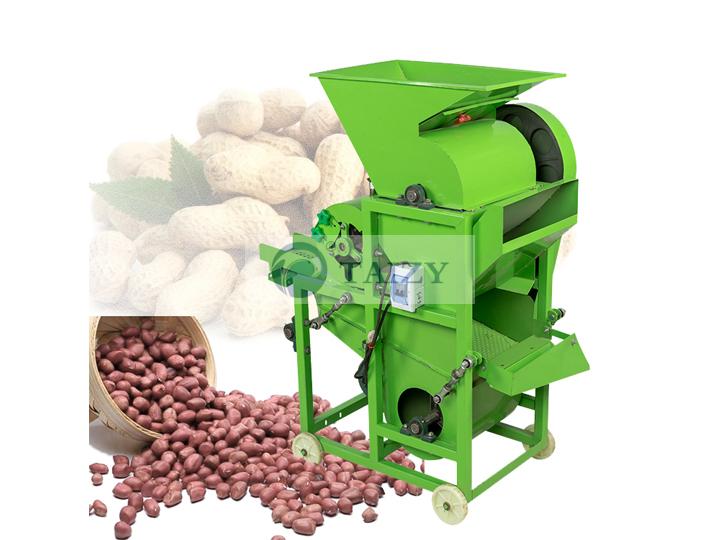

The peanut shelling machine has the advantages of being compact, lightweight, easy to move, simple to install, high production efficiency, and good cleaning effect. So you can also take this machine to the field to work. For TBH-200 groudnut sheller, there is one screen. And we have different screens that have different gaps. We will recommend you a suitable gap screen to you. As for the power, our peanut shell removing machine can work with an electric motor or, a gasoline engine.

Structure of groundnut shelling machine

The groundnut shelling machine is mainly composed of an inlet, screen, roller, shaft, peanut kernel outlet, fan, power source(electric motor, gasoline engine), etc.

Working flow of peanut sheller

- Firstly, start the groundnut sheller. Then put the peanut into the inlet quantitatively, uniformly, and continuously.

- Secondly, the peanut shell is broken under repeated blows, friction, and collision of the rotor.

- Thirdly, under the rotating wind pressure and blow of the rotor, the peanut granules and broken peanut shells pass through a screen.

- Then, the rotating fan will blow the peanut shell out of this peanut shell removing machine. The peanut granules will be screened by a vibrating screen to achieve the purpose of cleaning.

Working video of peanut shelling machine

Parameter of groundnut shell removing machine

| Model | TBH-200 |

| Power | gasoline engine or electric motor |

| Capacity | 200-300kg/h |

| Weight | 65kg |

| Size | 650*560*1000mm |

| MOQ | 10pcs |

Advantages of peanut shelling machine

- High productivity. capacity is 200-300kg/h. And clean shelling. Peanuts after shelling have almost no impurities.

- Low loss rate and small breakage rate. There are very few broken peanut kernels.

- The structure is simple, the use is reliable. The peanut shelling machine has a long service life.

- The adjustment is convenient, and the power consumption is low.

Precautions of groundnut shell removing machine

1. Before use, check whether the fasteners are tightened. Whether the rotating part is flexible and whether there is lubricating oil in each bearing.

2. We should feed peanuts evenly and in an appropriate amount. The material should not contain iron filings, stones, and other sundries to prevent breaking the peanuts and causing mechanical failures.

3. Before storing the machine, remove the dust, dirt, and remaining seeds on the surface of the machine. Then repaint the painted parts. After the paint is dry, cover the machine and store it in a dry warehouse. We should remove the belt and hang it on an indoor wall that will not be exposed to the sun.

Contact us at any time

If you are interested in our advanced small peanut shell removing machine, please feel free to contact our professional team for more details. Further, we warmly welcome you to visit our factory and experience the performance of our machines for yourself. We look forward to providing you with the best quality products and services!