40Ton/Day Automated Paddy Husking And Milling Line

Taizy’s 30 tons per day output paddy husking and milling line is a set of highly efficient automated rice processing systems. The line includes a storage bin, water polishing, color sorting, and necessary essential infrastructure equipment, providing an integrated solution for farmers and rice processors, and reliable support for the modernization of the agricultural production chain.

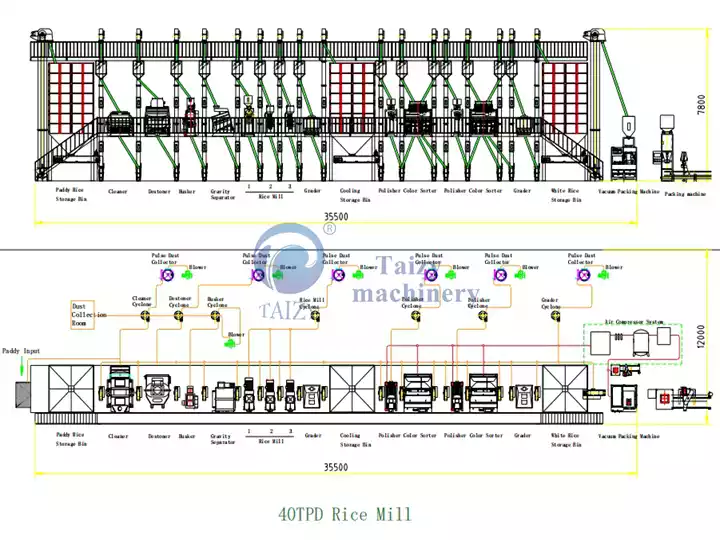

40TPD Paddy Husking And Milling Line Structure

The line goes from right to left, starting with a pre-cleaning machine, followed by a destoner machine (also available as a comprehensive cleaning and de-stoning machine), then the familiar huller, gravity grader with three passes of rice (or you can use just two mills), followed by a bin and a water polisher, color sorting, vacuum packing, and a packaging machine. In addition, you will use a degassing tank and air compressor.

Best Humidity of the Paddy Rice for Milling

- The best humidity of the paddy rice should be 14.5%, and the rice breakage rate should be around 2% in the milling process.

- Lower than 14.5%, breakage rate will be higher.

- Higher than 14.5%, the breakage rate will be higher, and part of the paddy husk and bran will be blocked inside the machine, affecting the machine’s normal running, even motor burns.

Uses of Steel Frame Platforms

- The bottom platform is used to make all machines of paddy husking and milling line on the same level to connect them working well together.

- The top platform is used to check and repair the elevators.

- If you can build the cement platform by yourself, you can remove it and reduce the related price.

Paddy Husking And Milling Line Successful Cases

Our company’s rice milling unit production line has achieved remarkable success, not only recognized in the domestic market but also frequent transactions worldwide, involving more than ten countries including but not limited to Saudi Arabia, Vietnam, India, Pakistan, Bangladesh, Thailand, Nigeria, Kenya, Egypt, Brazil, Peru, and other countries.

The production line is equipped with intelligent control system, which is easy to operate, reduces labor cost and improves production efficiency. In addition, after careful design, it is characterized by strong stability and high durability, which effectively reduces the maintenance cost of the equipment and prolongs its service life. These advantages make our rice milling unit production line stand out in the market and are highly praised by customers.

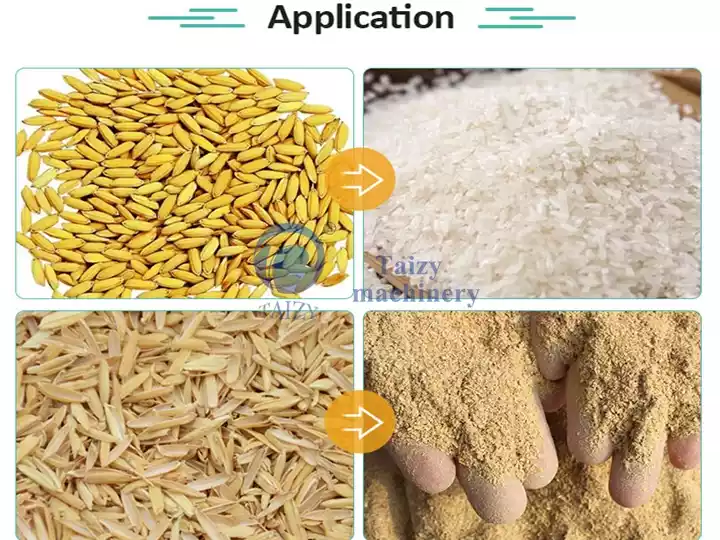

Rice Milling Line By-product Sorting

The by-product obtained from the paddy husking and milling line and finished product finishing is the mixture of bran and thresh, which contains not only rice bran and rice thresh (endosperm grains with a smaller grain size than that of small broken rice), but also complete rice grains because of the rupture of the hole of the rice sieve or because of the reason of improper operation, and so on.

- Rice bran has a high economic value, not only for the production of rice bran oil but also for the extraction of products such as gluten, calcium phytate, etc., as well as for the production of feed.

- The chemical composition of rice thresh is the same as that of whole rice, so it can be used as a raw material for making sugar and wine.

- Whole rice grains need to be returned to the rice mill for further milling to obtain a higher yield.

- Broken rice can be used to produce high-protein rice flour, to make beverages, to make wine, and to make convenient porridge.

For this purpose, it is necessary to separate rice bran, rice thresh, broken rice, and whole rice one by one, to make the best use of it, which is called by-product sorting.

If you are interested in paddy husking and milling line white rice processing technology, welcome to visit this page: https://www.agriculture-machine.com/rice-mill-category/ to see more configurations, and you can always contact us, we design the most suitable program for you.