4-15t/h grass cutting machine / cutting wet grass / grass cutter

4-15t/h grass cutting machine / cutting wet grass / grass cutter

Chaff cutter/Silage cutting machine

Features at a Glance

9RSZ series of grass cutting machines is to cut all kinds of grass and bears high working efficiency, that is, 4t-15t/h and different models have different capacities. Grass cutters can crush grasses into filiform shapes, which can improve the digestion of the stomach when feeding animals.

type one: 4t/h chaff cutter

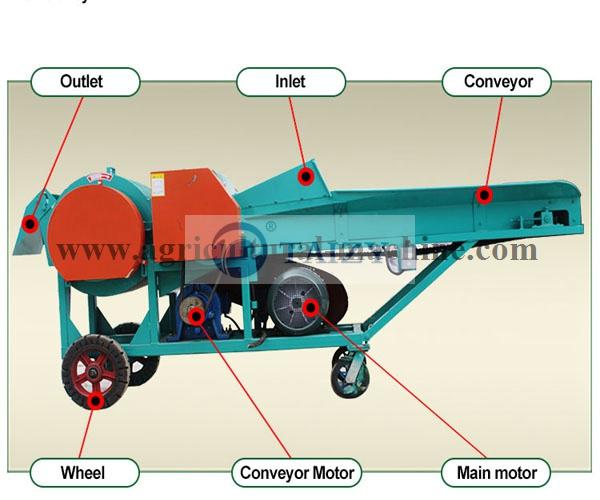

Structure of grass cutting machine

1. Discharge outlet 2. Body 3. Rotor 4. Feeding and shredding device 5. Geared motor 6. Feeding slot 7. Rack 8. Protective cover 9. Rotor motor 10. Walking wheel

Technical parameter of grass cutter

| Model | 9RSZ-4 | 9RSZ-6 | 9RSZ-10 | 9RSZ-15 |

| Power | 7.5KW | 15+2.2KW | 22+3KW | 30+5.5KW |

| Width of the feeding tray | 2860r/min | 2860r/min | 2860r/min | 2100r/min |

| Capacity | 4t/h | 6t/h | 10t/h | 15t/h |

| Blades quantity | 32PCS | 40PCS | 48PCS | 64PCS |

| Width of feeding tray | 240mm | 300mm | 500mm | 800mm |

| Throwing distance | More than 2300mm | More than 2300mm | More than 2300mm | More than 2300mm |

| Dimension | 2000*750*800mm | 3000*900*1050mm | 3600*930*1240mm | 4200*1170*1250mm |

| Weight | 300kg | 980kg | 1100kg | 1400kg |

type two: 6t/h chaff cutting machine

Working principle of grass cutter

1. Turn on the rotor motor.

2. Turn on the automatic geared motor to drive the automatic feeding device after the operation is stable.

3. The operator evenly spreads the straw on the automatic feeding plate and the inlet gradually, and raw material goes into the drum from the cutting device at a high speed.

4. Blades hit tear, and smash them into a filament shape at this time.

5. Finally, grass is thrown out of the machine by centrifugal force.

type three: 10t/h 16t/h chaff cutter

Advantages of grass cutting machine

- Cutting grass machine adopts chain automatic feeding device that is suitable for forage with long diameter, saving labor time.

- Double-pushing roller suction and cutting device to enable a good cutting effect without any blockage, improving working.

- The cutting grass machine is equipped with a detachable walking wheel for easy movement.

| Common malfunction | Reason | Solution |

| The raw material is blocked or Overload shutdown | Put excessive grass or place them unevenly | 1. take out the grass 2. reduce the amount of grass 3. Put grass into the inlet evenly |

| Abnormal sound in the crushing part

Abnormal sound in crushing part | screw is loose | tighten the bolt |

| metal or stone is in the machine | Stop the machine to check machine and replace spare parts | |

| The cotter is broken and the hammer is moving | The cotter is broken and hammer is moving | |

| The cotter is broken and the hammer is moving | Change the cotter | |

| A violent shake of the machine

| a violent shake of the machine

| Reinstall according to the arrangement |

| The weight deviation of the two sets of hammers is excessive | weight deviation of the two sets of hammers does not exceed 5g. | |

| Individual hammers are not locked | making the hammers flexible | |

| some rotors are unbalanced or worn out | The spindle has been bent | |

| The spindle has been bent | Straightening spindle or replacing

| |

| Bearing is damaged | Replace the bearing | |

| anchor bolts | tighten anchor bolts

| |

| The split pin is damaged and the hammer is axially moved | stop grass cutting to clean | |

|

Machine is inflexible | Rotating parts entangled grass | stop grass cuttin to clean |

| Bearing is damaged | Replace the bearing

| |

| Lack of lubricating oil | Add lubricating oil on time | |

| Outlet is blocked | V-belt is damaged or loosed | replace or tension the V-belt

|

| The crushing part is blocked | remove the impurity | |

|

Bad crushing effect | hammer and crushing device are damaged | Replace hammer and crushing device |

| Low spindle speed | Properly adjust the tension of the V-belt | |

| Bearing is overheating | Properly adjust the tension of the V-belt Adjust the V-belt to a proper tension | replace bearing |

| Too much or too little lubricating oil | add proper lubricating oil | |

| Properly adjust the tension of the V-belt | Properly adjust the tension of the V-belt

Adjust V-belt to a proper tension | |

| The spindle is bending or the rotor is imbalance | Straighten or replace the spindle, balance the rotor | |

| Long-term overload work | Reduce the amount of grass | |

| V-belt is overheating | Improper tightness of the V-belt | Check and change the belt pulley |

| The belt pulley groove is worn or the surface is rough | Check and change the belt pulley | |

| The main pulley and the power pulley axis are not parallel, and the belt groove is not aligned.

| The main pulley and the power pulley axis are parallel, and the belt groove is aligned. |

List of major parts and consumable parts of grass cutter

| Number | Name | Function | Quality Assurance Period |

| 1 | bearing | Tension chain wheel | 3 month |

| 2 | bearing | conveyor | |

| 3 | bearing | upper roller | |

| 4 | bearing | Under roller | |

| 5 | bearing | spindle | |

| 6 | roller chain | inlet | |

| 7 | conveyor roller chain | inlet | |

| 8 | V-belt | rotor | 1 month |

| 9 | V-belt | Inlet | |

| 10 | reverse switch | inlet | 3 month |

| 11 | electrical cabinet | electrical control

| |

| 12 | hammer | 1 week | |

| 13 | hammer shaft | 1 month | |

| 14 | Cutting part | ||

| 15 | the sliding sleeve of the upper roller |

FAQ of grass cutter

What should I do if there is blocking?

The reverse switch can be pulled to “stop”, and then pulled to the “reverse”.It is strictly forbidden to remove the blocked straw by hand without stopping the grass cutting machine.

How to increase the gap of the roller?

First, loosen the center screw on the upper plate of the grass cutting machine, and adjust the sliding plate and sliding block clockwise.

Second, adjust the bolt on both sides counterclockwise to the appropriate position. The gap between the two rollers should be Horizontally the same, and the upper and down rollers should be flexible.

Finally, tighten the bolt on the center screw.

Adverse action will decrease the gap.

Contact us at any time

Whether you’re a large-scale farm or a smallholder, our grass cutting machines offer you an efficient and convenient solution for grass handling. Feel free to contact us anytime and our professional team will be happy to provide you with detailed information about the machine, customization options, and more related services.