30TPD Modern Integrated Rice Hulling Plant

The 30TPD Rice Hulling Plant is usually suitable for medium to large-scale rice mills or processing plants to meet the market demand for edible white rice. There are various tonnages and configurations of rice milling equipment to choose from, which you can view by clicking on this page: https://www.agriculture-machine.com/rice-mill-category/.

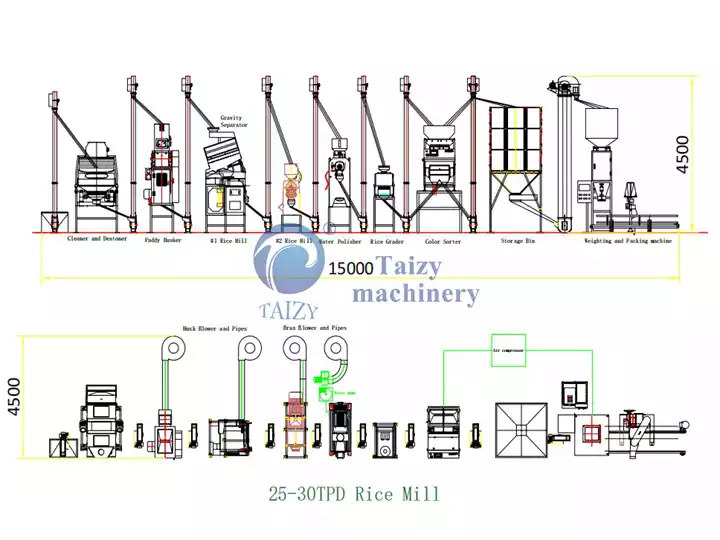

30TPD Rice Hulling Plant Main Equipment Components

The combination shown below is relatively simple, with the workflow proceeding from left to right, with a de-stoner, huller, gravity classifier, rice miller, a second rice miller, plus a white rice grader. This is similar to the 15-ton per day extended line(15TPD Rice Mill Production Line With Polisher And White Rice Grader), except that each machine has been made larger.

Of course, depending on your needs, you can also add a water mist polisher. You can also continue to add color sorting, bins, and packaging machines at a later date.

30Ton/Day Rice Processing Line Economic Benefits

- High return on investment: Because this rice hulling plant has a highly efficient production capacity that allows for a significant increase in output and thus a faster return on investment, investors can expect a high return on investment.

- Lower production costs: The automatic control system allows for intelligent production, which reduces waste during operation and effectively lowers labor costs and energy consumption.

- Improved output and efficiency: More raw materials can be processed efficiently. This is essential for coping with fluctuations in market demand, handling large orders, and improving the company’s resilience.

- Strong market competitiveness: Thanks to the efficient production capacity and superior product quality, investors can occupy a favorable position in the market. It can establish a good brand image for the enterprise, increase market share, and attract more customers.

Basic Principles of Rice Milling

Brown rice has a relatively smooth and tough skin layer that has a certain linkage with the endosperm so the removal of the skin layer requires some external force to break this linkage.

Currently often used in a variety of rice millers, is the use of the rice machine milling white room components and the mechanical force generated between the rice grains and the collision friction between the rice grains and rice grains to make the brown rice milling white.

Product Quality Assurance

- Efficient Screening System: The leading color sorting technology can be adopted, which can efficiently screen out foreign materials and inferior products to ensure the purity and quality of the final products.

- High-quality material selection: Key parts and materials are carefully selected to ensure good wear resistance, stability, and corrosion resistance, which prolongs the service life of the rice hulling plant equipment.

- Strict Quality Inspection Process: Strict quality inspection points are set up during the production process to ensure that each product meets the high standard of quality requirements through multiple rounds of multi-dimensional testing.

- After-sales service support: We provide comprehensive after-sales service, including training, maintenance upgrading, etc., to ensure that customers can get timely support during the use process and keep the equipment running efficiently.

Successful Cases

Our rice milling unit production line has been sent to Nigeria, Togo, the Philippines, Ghana, Malawi, Iran, India, and other countries. The following are some of the prominent cases:

- An Indonesian rice mill introduced our 30TPD rice hulling plant, significantly increasing its production capacity. They reported a 30% increase in production and a significant improvement in product quality after the equipment was put into operation.

- A smallholder farmer in Bangladesh successfully automated the rice milling process using our production line. This not only improves production efficiency but also opens up a wider market for his products.

- A Vietnamese rice mill adopted our unit and successfully improved the quality of rice through advanced color sorting technology. This helped them establish their brand image in the competitive market.

Whatever your needs are, please feel free to contact us and let us know. Our business managers will be happy to assist you with the most appropriate and economical solution.