25TPD Rice Milling Line With Steel Frame

Taizy company offers a 25 tons per day output rice milling line that carries a sturdy steel frame configuration designed to provide an efficient and reliable solution for your rice production. The 25 tons per day capacity ensures that you can cope with large-scale rice milling needs for both medium and large rice producers.

Meanwhile, we also have the same production line without a steel frame available, please click to view: the 25Ton/Day Rice Miller Unit Without Steel Frame.

This Paddy Processing Line’s Main Features

- Sturdy Steel Frame: Designed with high-quality steel, the structure is sturdy and durable, ensuring the stability and long-term reliability of the whole production line.

- Highly customizable: You can choose the appropriate configuration according to your production scale and requirements, enabling highly personalized customization of the rice milling line.

- Space-saving: The compact and sturdy steel frame structure not only provides strong support but also effectively utilizes plant space to ensure an efficient layout of the equipment.

- Flexible Configuration: It can be customized according to the customer’s needs, including components such as rice milling machine type, polishing machine, color sorter, etc. to meet different rice milling requirements.

The underlying platform is strategically integrated to ensure that all machines operate seamlessly at the same level. This not only promotes a harmonious workflow but also facilitates efficient connectivity between the various components. The top platform provides a convenient space for elevator inspections and maintenance, reducing downtime and improving the overall life of the unit.

Three Kinds of Rice Milling Lines with Steel Frame

Rice milling production lines can be combined in a variety of ways. Three configurations are listed below, briefly describing the composition of each line.

Type 1

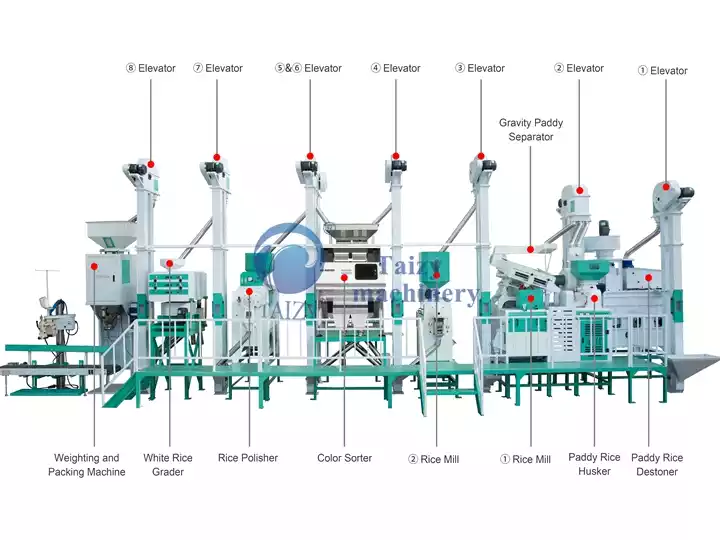

This rice milling line combination is a conventional paddy rice destoner, husker, gravity paddy separator, two rice mills, then followed by a color sorter, polisher, white rice grader, and a weighting and packing machine.

Type 2

This set is basically the same as the Type 1‘s, with the only difference being the replacement of the polisher with a water-mist polishing machine, plus the addition of a storage bin after the white rice grader.

Type 3

Compared with the above two configurations, this set uses three rice mills to make the rice of higher quality. It also uses an advanced vacuum packaging machine to ensure the freshness and quality of the rice and extend its shelf life.

Factory Show and Customer Visit

Welcome to visit our factory. We stand out with our strong inventory and efficient logistics to ensure timely delivery to meet your needs.

Rice Milling Line Aftersales Service

- After we finish all the rice milling line machines, each part will be labeled with a tag. We also provide operating instructions for each machine.

- We install each part in our factory and take a clear video of the installation process. You follow our pictures and videos for installation.

- Any questions, you can take pictures and videos, we provide online service. Or we can video chat directly.

- We can arrange for engineers to your place to guide the installation, debugging, and training staff.

- Except for wearing parts, human damage, and improper operation, the main equipment and motor are guaranteed for 1 year, and we provide lifetime online technical support.

To learn more about rice solutions, visit this website https://www.agriculture-machine.com/rice-mill-category/. Any questions, please feel free to contact us, we provide you with the optimal solution!