25Ton/Day Rice Miller Unit Without Steel Frame

Recently, our proud rice miller unit that can process 25 tons of grain per day has been successfully offered for sale again. Different from the traditional design, this production line purposely removes the steel frame configuration, making the whole more compact and convenient, adapting to all kinds of plant space limitations.

Of course, we also have the corresponding production line with a steel frame structure, please click to view: the 25TPD Rice Milling Line With Steel Frame.

Five Configurations of Rice Miller Unit Show

Among the product lines that our company is proud of, the 25 tons per day output rice milling unit is not only known for its high output but also popular among customers for its multiple configurations to flexibly respond to different needs. You can choose them all according to your needs and budget.

Five combinations are briefly listed below. Of course, if you have other ideas, feel free to contact us and we will recommend the most suitable option for you.

Type 1

This is a relatively simple rice miller unit combination, and the machines included in the entire line are, in order, a feed hopper, a de-stoner, a rice huller, a gravity paddy separator, two rice mills, and a white rice grader. The overall configuration is the same as 15T/D(15TPD Rice Mill Production Line With Polisher And White Rice Grader), but the size of each machine is correspondingly larger.

Type 2

This group of machines is based on Type 1 with the addition of an extra rice milling machine and a polisher, as well as a rice packaging machine at the end of the line.

Type 3

The combination of this rice miller unit is also relatively simple, just adding an extra color sorter and packaging machine at the end of Type 1. Among them, the color sorter detects the color and shape of the rice by means of a highly intelligent optical system, thus enabling the rejection of unqualified rice, color spots, foreign objects, and other problematic rice.

Type 4

This configuration builds on Type 1 by adding a water polishing machine immediately after the rice milling machine, plus color sorting and packaging equipment immediately after the white rice grader (details of the additional machines are shown on the right).

Type 5

The set is similar to the Type 4 configuration, with the difference being that the order of placement of some of the machines has been switched. The color sorter was placed after the first rice milling machine, the water mist polisher was placed after the white rice grader, and an extra storage bin was added immediately after to prevent the milling speed from keeping up with the packaging machine.

Design Drawing Service

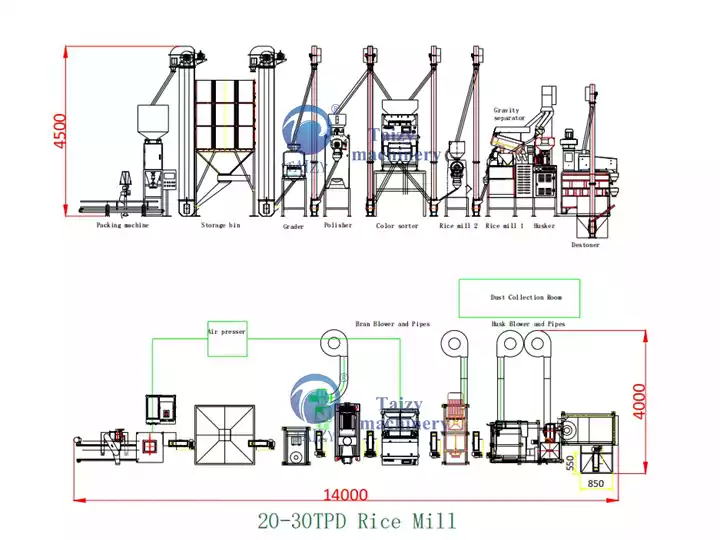

After receiving the deposit, you can send us the production workshop layout drawing. We will ask our engineers to draw the whole rice miller unit design according to your workshop size. An example drawing is given below.

Based on the five different rice miller unit combinations above, it’s easy to see that your options can be very flexible when it comes to purchasing a machine to process rice. You can choose whether or not to purchase certain additional machines, and you can also adjust some of the machines to suit your preferences. This versatility allows the line to meet rice production scenarios with different processing requirements.

For more rice milling production line configurations, please visit this website: https://www.agriculture-machine.com/rice-mill-category/, and feel free to contact us for consultation and quotation.